Last semester, Simplexity presented a challenge to students at the University of California, San Diego and Portland State University: test buttons. This was a capstone design project for the students, which is an opportunity for graduating senior engineers to showcase the tools, analytical skills, and general engineering creativity they have gained to solve a design problem. The students confront a problem with given design constraints like size and budget. They must then design, build, and test a solution. In this case, that solution was an automated button life tester.

Many of the products Simplexity designs have buttons. Because buttons degrade with usage, button testing is sometimes necessary in product development. We asked student teams at each of the universities to design and build a button-testing instrument. It’s instrumentation like this that allows Simplexity to provide its clients with high-value, reliable products.

Creativity in constraints

We gave the students relatively restrictive design constraints, but they showed creativity in their solutions. Each instrument needed to hold test samples of various shapes and sizes and reliably cycle a pushing “finger” for millions of cycles with a force-limited, human-like touch. Furthermore, it had to be able to move between buttons and press them in sequence. Finally, to showcase its capabilities, Simpexity’s Mechatronics Board controlled the button-pressing instrument.

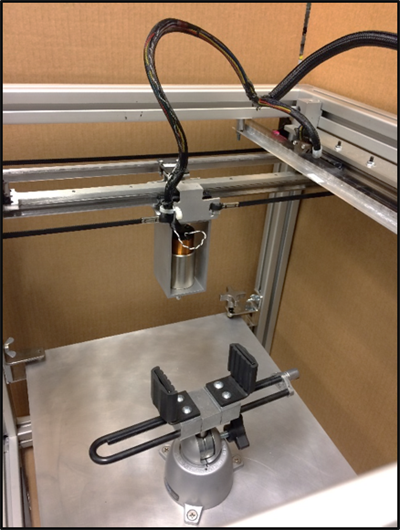

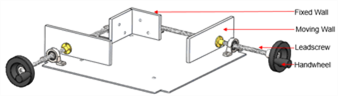

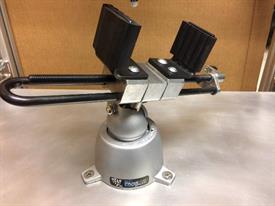

The two teams ended up with different solutions to the same challenge. To immobilize the test sample, the UCSD team’s architecture used lead screws to bias the products against reference surfaces. This gave them the flexibility to hold and test a wide variety of product shapes and sizes and removed the need to recalibrate with every test. The PSU students used an articulating panavise. This held curved products with odd angles well, but it didn’t offer the repeatability of the UCSD team’s design.

UCSD’s screwed-in design

PSU’s articulating panavise

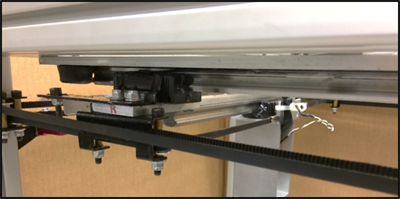

The two teams also had different approaches for moving from one button to another. The UCSD team used stepper motors and linear stages to move from button to button, while the PSU team used DC motors and toothed belts in a CoreXY layout.

Pushing the buttons, testing the buttons

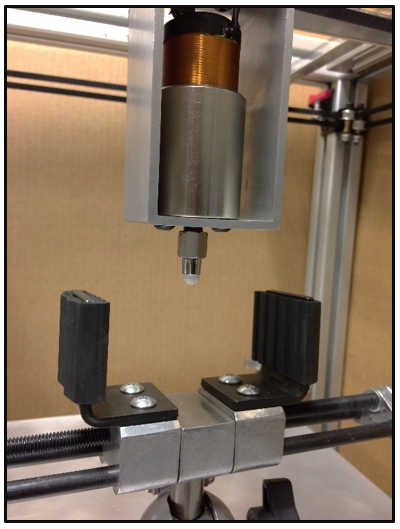

The act of pressing the button was also achieved in different ways. While the UCSD team went for control with a gear train, cam, and force-limiting spring, the PSU team went for speed with a voice coil.

While very few things were the same between the two teams, both recognized the importance of replaceable rubber presser tips for their devices. The PSU team decided to use replaceable tips intended for a touch-screen stylus. UCSD’s project added the capability to change tip designs for more compliance or longer tip life. Their design had a silicone “finger” that offered a softer touch, but it may degrade more quickly and need more frequent replacement.

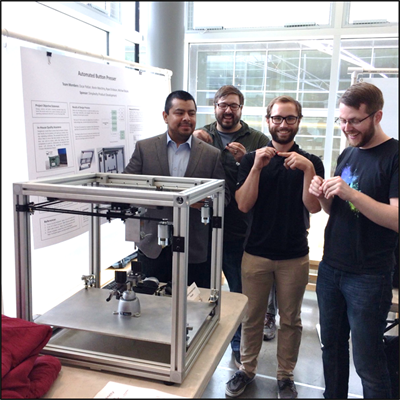

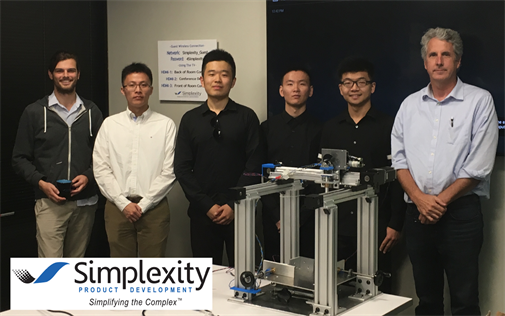

Once finished, both teams presented their solutions to Simplexity and their respective universities. Their results are a testament to how different design teams can find unique solutions to the same problem. Take a look at what they came up with!

The UCSD team with their finished button pushing device

You can see the UCSD Button Pusher project page here.

For more on topics related to product design and testing, follow Simplexity’s product development blog.