Embedded Motion Solutions

How can Simplexity deliver lower risk AND faster time-to-market in addition to competitive product cost? We have invested many years and hundreds of thousands of dollars to design, build, and test mechatronic solutions for the embedded motion space. This is analogous to what industrial component suppliers have done for the low-volume markets, but our solutions are optimized for the mid- to high-volume product space.

Introducing Simplexity SNAP

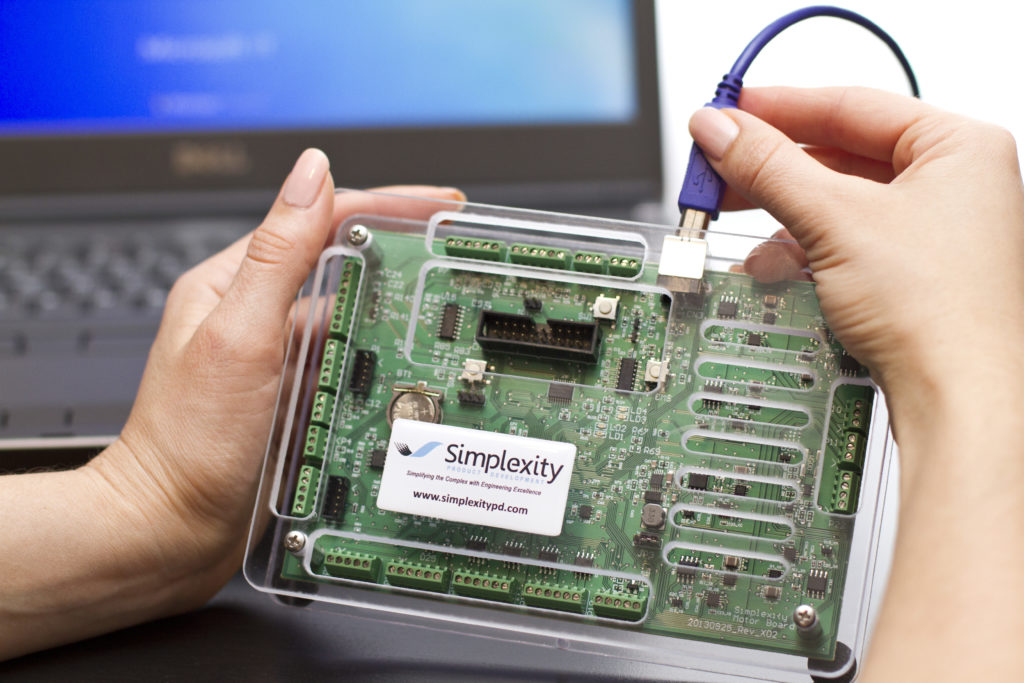

Simplexity’s SNAP is an all-purpose mechatronics board that speeds up time to market by allowing firmware and controls teams to start working in parallel with the electrical team. As a result, mechanical prototypes start moving sooner too. Early development on the SNAP board will eventually transition to a custom PCA into which the existing firmware can be ported seamlessly. You own the design of this custom PCA, giving you complete control over the product life cycle. In short, SNAP will jump start your product development, so you don’t have to begin with a blank sheet of paper or use expensive industrial components.

SNAP can be used in two ways:

- As a development kit to immediately start running motors and developing firmware.

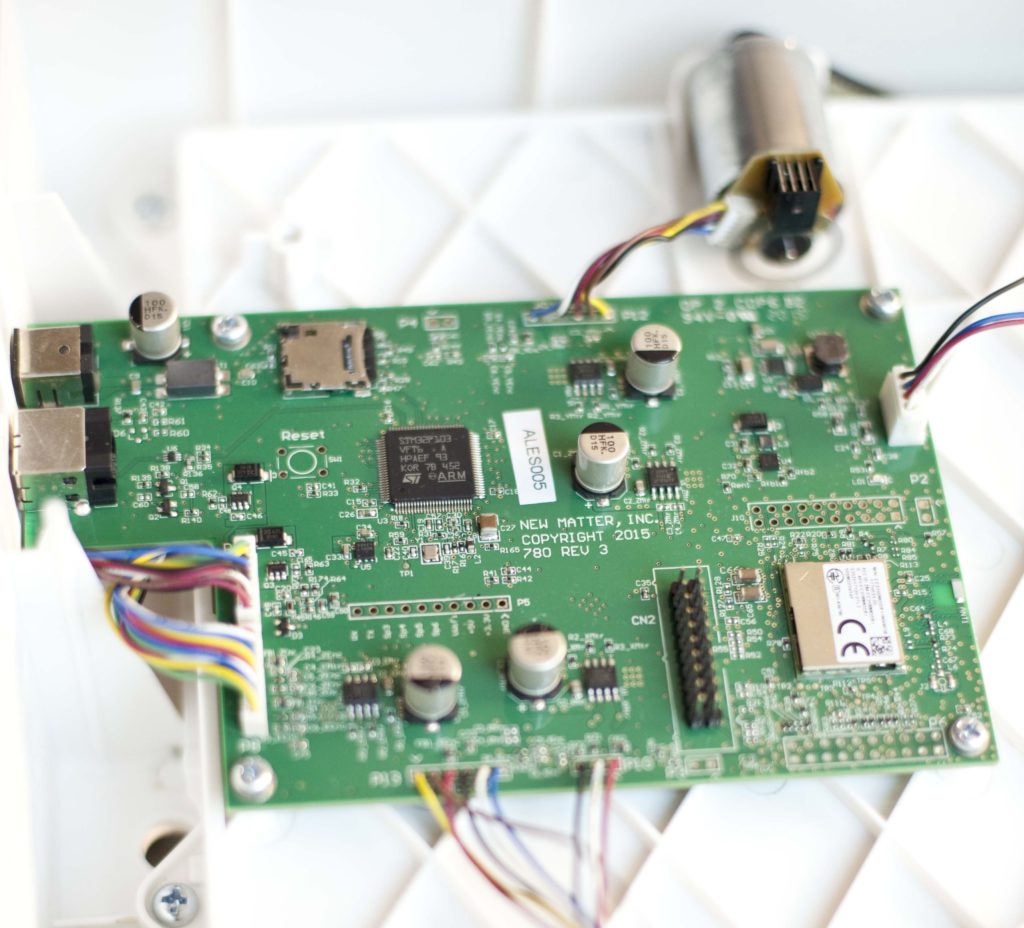

2. As a reference design to customize the functionality needed only for your application. One example of an optimized version of the above PCA as installed in a New Matter 3D Printer is shown below.

SNAP Software and Firmware

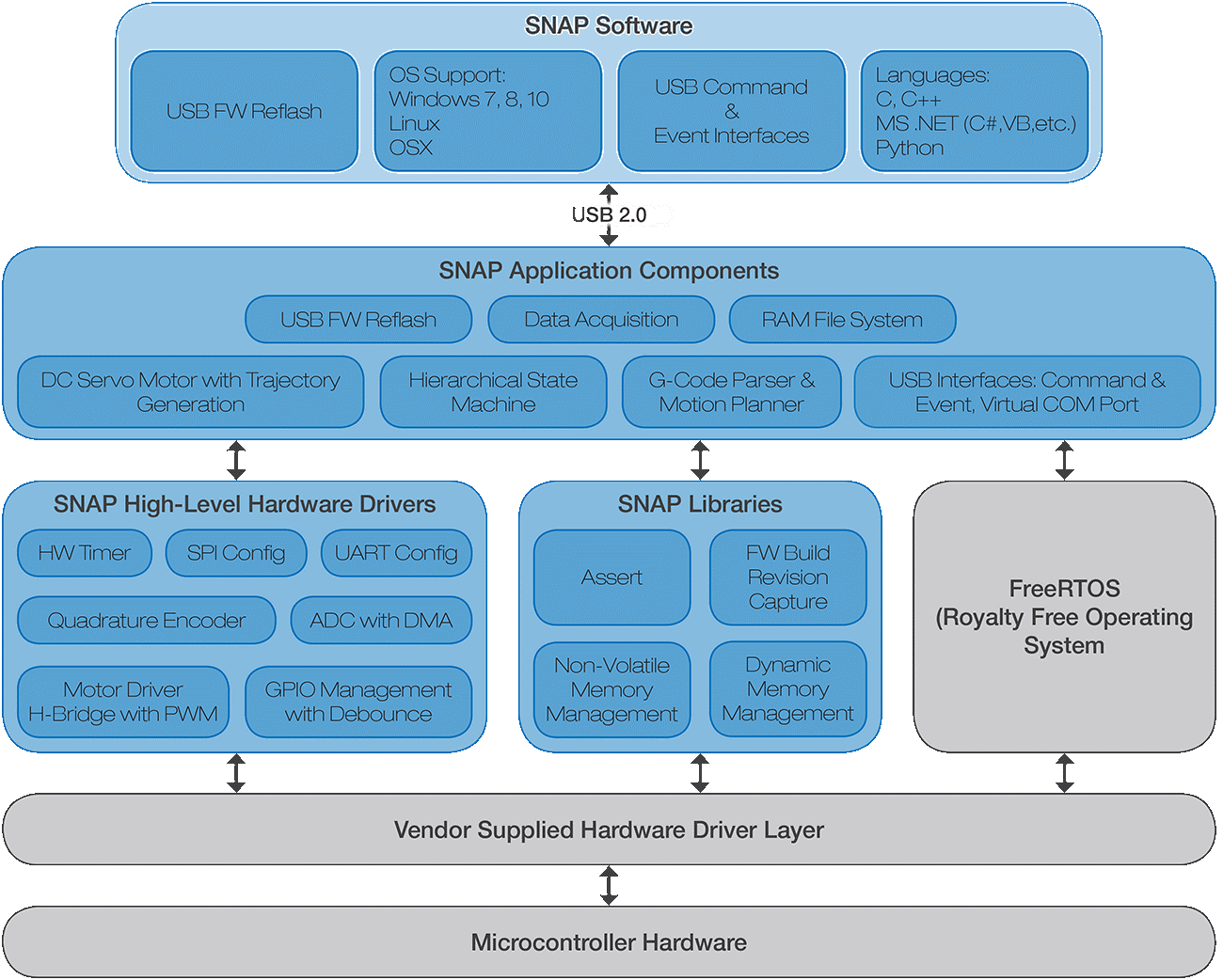

SNAP’s companion software and firmware components, developed by Simplexity, provide several important benefits:

- Solution provides a full firmware architecture tailored for products, including components for hardware drivers and higher-level product behaviors. This provides faster time-to-market and reduces your development cost

- Risk is reduced using validated firmware components, and vendor drivers that have been patched for errata

- Unlike with open source code, you own the IP in your product

The below diagram shows the stack of firmware that has been developed. The blue areas are Simplexity SNAP components, drivers, and libraries.

SOPHISTICATED CONTROL SYSTEM SOLUTIONS

A motion system is only as good as the algorithms used to drive it. Simplexity has already developed and proven control algorithms for most common motion needs. Whenever advanced control is needed, we have flexibility to readily implement custom solutions. Our thorough analysis capabilities allow us to simulate prototypes before hardware is ready, thus reducing risk and pulling in schedule.

The standard motion control firmware offering provides:

- PID feedback + 3 term feedforward control loop for brushed DC motors

- Fully customizable trapezoidal velocity profile generation

- Axis-to-axis motion synchronization including slaved axes.

- On-the-fly commanded motion profile modification.

Future functionality includes:

- Full G-code interpreter

- Field oriented control (FOC) of Brushless DC motors

PROVEN TRACK RECORD CUSTOMIZING MECHANICAL COMPONENTS

Simplexity has accumulated decades of knowledge of how to customize mechanical components for mid- to high-volume applications. We offer competitive product costing via relationships with component suppliers to use proven mechanical components that scale with volume. If applicable, we can optimize your gear trains with proprietary gear analysis tools to reduce risk before committing to expensive tooling.

Key mechanical motion components that affect function, reliability, and cost are:

- Motors. We have tried many different types of motors and have vetted motor vendors to receive favored pricing on certain models for our clients.

- Encoder systems are often an expensive component of the drive system. Simplexity has decades of experience understanding how to develop low cost, compact, and high-performance encoder systems.

- For applications using off-the-shelf motion stages, convert to custom motion mechanisms for higher volumes. Rather than paying $2K-$5K per axis of motion, our mechanical solutions maintain precision in the tens of microns, while reducing bill of materials cost by as much as 50%.

- Gear trains, belt drives, and lead screw drives for mid to high volume products. Systems are optimized for loads, speeds, position accuracy, cost, and tooling return on investment.