PRINTER DEVELOPMENT: INTEGRATING PRINTING INTO NEW PRODUCTS

If you are interested in developing a product with embedded printing technology, we’d love to help. Simplexity was founded by ex-HP engineers and employs a team with decades of printer development experience. HP’s Specialty Printing and Technology Systems (SPTS) division has selected Simplexity Product Development as one of their preferred solution integration partners.

Watch the video below to learn more about Simplexity’s printer development expertise:

WE CUSTOMIZE TO MEET YOUR PRINTING NEEDS

Whether your project requires a new printer design, an improvement to an existing design, or customized printer logic in an existing Hewlett Packard (HP) platform, we have the knowledge and experience to help you succeed.

In addition to working with HP’s 2D Thermal Inkjet (TIJ) printing technologies, we have also created designs for:

- High speed, Page Wide array printing systems

- Piezoelectric-based printing mechanisms

- 3D printing systems with HP MultiJet Fusion (MJF) technology

- Customized 3D/Additive printing systems

Select examples and specific engineering skill sets from numerous printer integration projects are given below.

PRINTING APPLICATIONS

- Inkjet printer development, including page-wide array printer design

- Custom OEM label printers

- Adding color inkjet to a Braille printer for vision-impaired users

- Oil & Gas Well Log continuous media printer

- Non-traditional media applications (fingernails, concrete)

- Rugged use and Zero gravity printing for the International Space Station

- 3D Printing & Additive manufacturing solutions

- Digital printing press development for high volume printing applications

SIMPLEXITY SKILL SETS IN PRINTER DEVELOPMENT

Particular areas of expertise:

Embedded firmware development, including:

- FPGA print image processing from input image to pen data format.

- General-purpose printing system algorithms to custom designs

- Motion control algorithms for low cost, high accuracy control of print head and print media.

- Simplexity toolkit for rapid deployment of custom FW development solutions

Mechanical system design, including:

- Paper path and media handling systems

- Mechanism design including custom printer transmission and precision gear design

- Sheet metal structural design

- Case/Enclosure plastic part design

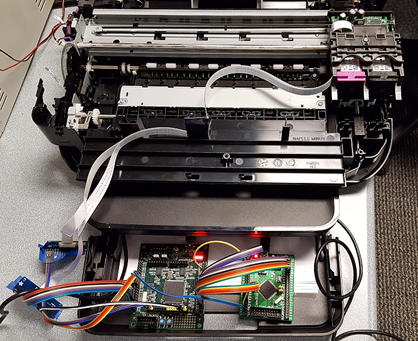

Electronics design, including:

- Integration or HP and other print head drive electronics and nozzle control for ink delivery

- Custom printed circuit board assembly (PCBA) design

- Flex circuit design

- Power management

- Designing for rugged environments

Ink delivery and print head maintenance, including:

- Deep engineering experience with driving and controlling both thermal and piezo-electric print head technologies

- Ink cartridge and printhead health/reliability algorithm and mechanism development

- 3D printhead feed rate & temperature control for filament dispense

DESIGN FOR COST AND MANUFACTURING (DFM)

Most printer development clients require some form of manufacturing ramp. They rely on our expertise with a number of aspects of design manufacturing readiness including:

- Low-cost solution architecture & development for low to high-volume manufacturing

- Custom part and assembly cost reduction expertise across printing architectures

- Part and assembly evaluation, testing, and verification expertise

- Deep experience with New Product Introduction (NPI) processes, supplier qualification and transition to manufacturing

AN EXPERIENCED PARTNER

We have spent nearly two decades innovating in the field of printer development and many of our engineers have decades of experience working for industry leading printer development companies. Contact Simplexity to discuss your next printing development project.