Last Fall, I got the opportunity to take a short trip down to San Francisco and attend the free AWS (Amazon Web Services) IoT Builders Day workshop. This event was… Read More

AWS AND IOT EMBEDDED SYSTEMS

| by Kyle Finch

Last Fall, I got the opportunity to take a short trip down to San Francisco and attend the free AWS (Amazon Web Services) IoT Builders Day workshop. This event was… Read More

| by Tim Kutscha

Have you run your firmware, found a repeatable bug, but weren’t able to reproduce the issue when single stepping through the code with your debugger? Maybe your internal watchdog block… Read More

| by Doug Harriman

A team from Simplexity recently attended Jack Ganssle’s “Better FW Faster” class. If you’re involved in the practice of embedded systems firmware engineering, you’ve probably heard of Jack and likely… Read More

| by Bryan Clark

Tunnel vision. Every engineer suffers from it at one time or another. A programmer gets so lost in the details they miss the forest through the trees. Instead of writing… Read More

| by Brian Peavey

Simplexity prides itself on simplifying product design. The simplest designs are often the most robust. This includes the design of embedded firmware. A major issue in developing firmware for an embedded… Read More

| by Asa Weiss

Drones are a great example of mechatronics in practice. They have many interconnected systems that depend on multiple disciplines to communicate and function as designed. In this article, we’ll explain how… Read More

| by Doug Harriman

The Bowflex SelectTech 560® (ST560) is a “smart” dumbbell, a piece of exercise equipment with embedded sensors and processing to provide training feedback during your workout. The ST560 has an… Read More

| by Gabriel Aldaz

In product development, choosing open versus closed hardware and software platforms requires careful consideration. Selecting open source hardware has advantages and limitations, concisely described in this blog post by Simplexity CTO… Read More

| by Doug Harriman

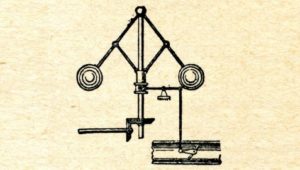

What is a Motion Control System? At the most fundamental level, a motion control system is any system that controls energy flow to generate mechanical motion with some desired properties…. Read More

The Simplexity team can be as involved in the production phase as requested by our clients. For clients with internal manufacturing or established relationships with contract manufacturers, our engineers are available to ensure quality is maintained and provide ongoing engineering support as needed.

Simplexity has a dedicated New Product Introduction (NPI) team that can guide the transition from design into production. The NPI team presents multiple options for manufacturing to the client, allowing clients to choose the solution that best suits their needs. This can involve Simplexity performing initial builds in-house prior to full handoff to a contract manufacturer or building the product via established relationships with contract manufacturing partners either domestically or overseas early in the process.

This phase occurs once the detailed design is complete, and prototypes are built with manufacturing-representative quality and detail. More extensive, formal testing is performed, such as life, reliability, safety, environmental, drop, and vibration.

The design team works closely with the manufacturing team to enable a smooth transfer, often with Simplexity engineers traveling to the contract manufacturer sites to ensure product quality. The design is transferred to the client based upon specific needs, most often after all tests are complete and the design is verified.

Phase 2C iterates on the learnings of Phase 2B and involves a refined prototype build of a fully integrated system. Some projects also benefit from additional iterations of the product based on prior learnings through additional phases (2D, 2E, etc), which are not represented in this graphic. All requirements are intended to be tested, and at the end of Phase 2 there will be confidence that the units will pass verification in Phase 3. The Bill of Materials is further refined, and the team updates estimates for the per unit cost of the product by receiving pricing from vendors and suppliers.

The detailed design phase usually has multiple, iterative sub-phases as the design progresses and representative prototypes are built. Phases 2B and 2C are typically the largest efforts in the product development process, where the specific implementation for all disciplines occurs (mechanical, industrial design, electrical, firmware, systems, software, manufacturing, and quality).

Simplexity typically engages with production component suppliers and contract manufacturing groups early in this phase to provide additional manufacturing input on the design. If the product has stringent testing or certification requirements, pre-screens are performed in this phase prior to formal regulatory agency testing.

Phase 0 is an optional phase for projects where the technical feasibility of the idea has not yet been fully proven. It can consist of research, concept work, exploring initial architecture, performing feasibility studies, and basic prototyping and testing.

The business and user requirements are converted into engineering requirements for the product. The project planning activity is based on the schedule, budget, risk, and initial product requirements. This process is best done as a collaborative team effort with the client, who has the deepest understanding of the market needs and user requirements.

The detailed design phase starts with defining options for the product architecture, with the goal of having the greatest chance of successfully meeting product requirements while best mitigating risk. Engineering activities in this phase include presenting options for hardware components, outlining the system block, sequence, and state diagrams, creating rough CAD, and breadboarding of high-risk subsystems. Results are presented with a description of the pros, cons, and key tradeoffs for each scenario.