CASE STUDY: VIEWPLUS COLOR INKCONNECT

Braille Color Printer that Makes Scientific Discovery Possible for Blind People

![]()

ViewPlus has developed a line of innovative braille and tactile graphics hardware and software solutions that make information that would otherwise be impossible for blind people to access, discoverable. The inclusive, accessible, and affordable products were designed to assist visually impaired people in their studies and careers by letting them feel colors, charts, and graphics that in the past were only available to sighted individuals. ViewPlus’ innovative products improve the learning environment for visually impaired and blind students and their teachers, especially in the S.T.E.M. (Science, Technology, Engineering, and Math) community.

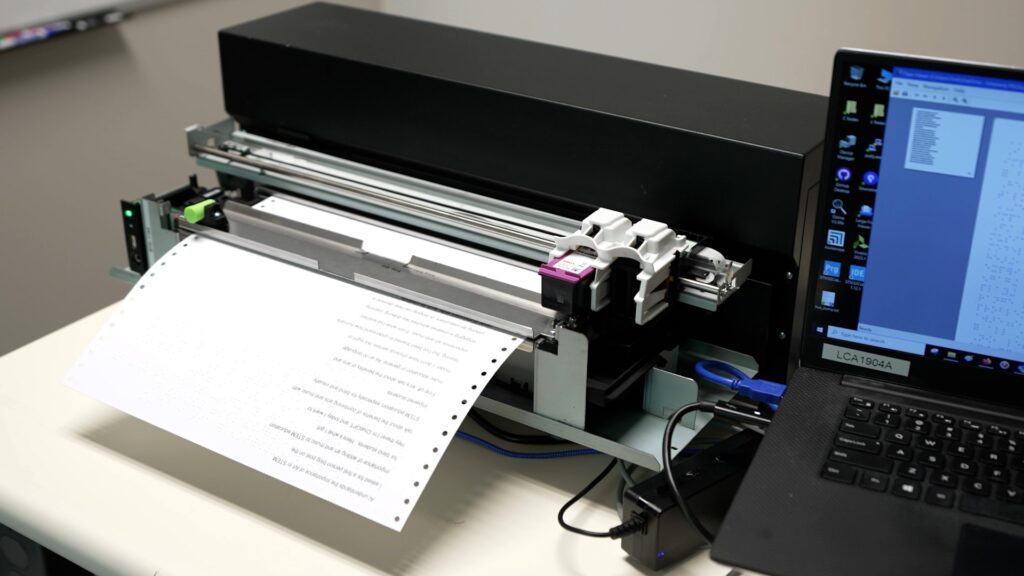

ViewPlus selected Simplexity Product Development to help develop their latest product, the Color InkConnect. This product combines fast and high-quality HP inkjet printing technology with braille and tactile graphics. It creates more detailed embossing and printing of formulas and plots, in real time so that visually impaired students and non-visually impaired professors can point and refer to the same information simultaneously. This revolutionary technology has improved the abilities of blind and visually impaired people to work, learn, and maintain independence.

This newly developed product will enhance learning material for non-seeing and seeing individuals, allow ViewPlus to create new unique content for non-seeing individuals, and significantly increase the quality of pictures and images overlayed onto braille.

ViewPlus Client Testimonial

THE CHALLENGE

The objective of the project was to create a new custom product that would meet the following objectives:

- Seamlessly integrate with the previous ViewPlus embossers.

- Be manufacturable at low and high volumes.

- Optimize the use of custom and off-the-shelf (OTS) parts to minimize product complexity and cost.

- Match output paper path of current embossers.

- Be cost competitive to ensure marketability.

- Provide the client with a successful transition plan to higher production.

- Support a large variety of print modes, such as dual pass printing.

THE SOLUTION

Simplexity designed a custom printer that encompassed high-end printer technology (leveraged from HP printers with the support of the HP SPTS team) and custom parts to allow for more advanced printer/braille technology.

This system can integrate with multiple embossers by using a custom adaptor piece that can be quickly and easily changed out between each embosser. This allows the end user to update or upgrade embossers without requiring a new printer system.

The new design uses a combination of custom and OTS parts to reduce cost and decrease repair time for any units in use, minimizing the unit’s down time. For all custom parts, the pieces were designed for low and high-volume production which reduces continued tooling investments as production increases.

The new system matches the output paper path of current embossers and sits directly in front of or behind the embosser (depending on which embosser is in use).

During development, Simplexity made design decisions that would create an easy transfer of the design back to ViewPlus for manufacturing including:

- Manufacturing at ViewPlus-approved locations.

- Quoting multiple vendors and recommending new manufacturers based on quality, history, and cost.

- Creating custom build, test, and inspection documentation that could easily be transferred to the ViewPlus team or any contract manufacturer.

- Creating new tooling and processes to aid in assembly, creating use and maintenance. documentation, and validating the process with qualitative results.

THE PROCESS

Simplexity first completed a Phase 0 Investigation to confirm the feasibility, initial estimates of scope, cost, and duration, and some defined risks.

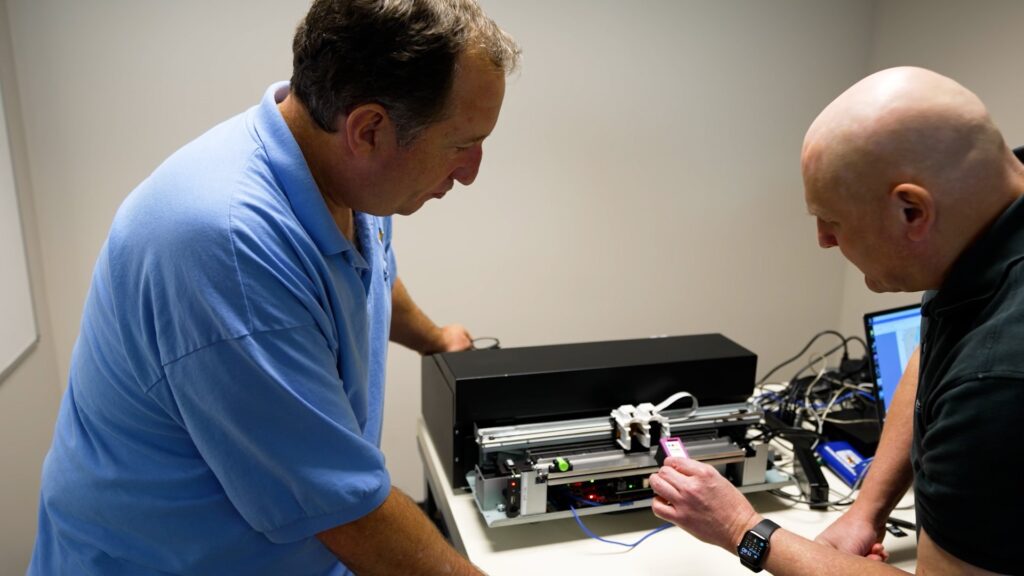

Moving into Phase 1-2A and Phase 2B, Simplexity completed the fully customized system to meet the requirements as defined with the client.

Simplexity’s full development included complete mechanical design, electrical design of custom PCAs and cables, and firmware and software design to implement the new behaviors and functionality.

Multiple risks were identified, and mitigation plans were completed to ensure the product was viable and producible.

The final design contained not only the Simplexity design team’s input but also underwent extensive client design reviews, submittals, and approvals prior to transitioning into prototype build and test.

To evaluate the new system, Simplexity completed a custom test plan, mapping each test back to the developed requirements. All attributes and functions were fully tested prior to delivery.

To ensure a clean and consistent build after design transfer back to ViewPlus, Simplexity developed custom tooling and fully documented processes for assembly and testing that can be maintained by ViewPlus or any contract manufacturer.

|

|

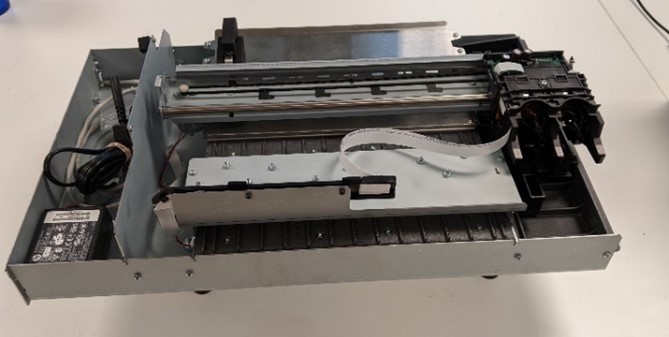

| Initial Proof of Concept Unit (Phase 1-2A) | Final Prototype (Phase 2B) |

See how ViewPlus is using their variable dot heights and patterns to represent color in tactile graphics and learn how their embossers can make information truly accessible.

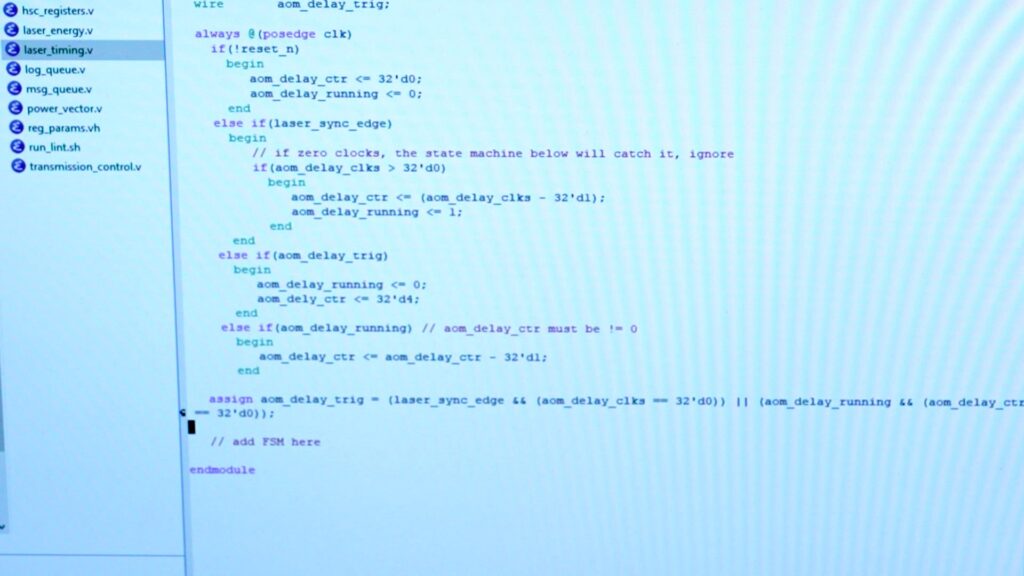

FIRMWARE ENGINEERING

- Created custom firmware to implement communication via ethernet as well as USB between the printer and embosser/computer.

- Created firmware to control all motors, encoders, and physical behavior of the printer system.

- Implemented printing quality of 600dpi and increased client capability to print a full-size page in less than 28 seconds.

- Enabled firmware updates via the USB port while protecting the unit security by removing any backdoor features.

- Implemented 3 print modes: draft single pass printing at 300x300dpi, normal single pass printing at 600x600dpi, and best dual pass printing with overlap masking.

- Implemented firmware controls based on all the sensors installed, including missing paper, paper jams, ink status, and multiple job processing.

- Implemented new audio capabilities to allow visually impaired individuals to troubleshoot the system.

MECHANICAL ENGINEERING

- Extended the width of a standard HP printer to match the width of the embossers.

- Designed custom parts which were manufactured by the client’s suppliers to allow for easy design transfer.

- Leveraged as many parts as possible from high-end printer technology including HP SPTS parts that could be purchased directly in large quantities.

- Implemented visual indicators (LEDs) as well as audio capabilities to ensure the unit could be operated by sighted individuals as well as visually impaired individuals.

- Designed a cover that allows all basic maintenance to be done through that one easily accessible area.

- Implemented sensors to ensure end user safety, printer protections, and easy troubleshooting, including paper jams, ink levels, and paper alignment.

- Created custom cables to allow for custom routing, preventing cable crimps, and preventing cable damage during maintenance functions.

- Designed final user Interface for multiple audio jack cable connections to prevent any user issues based on cable availability.

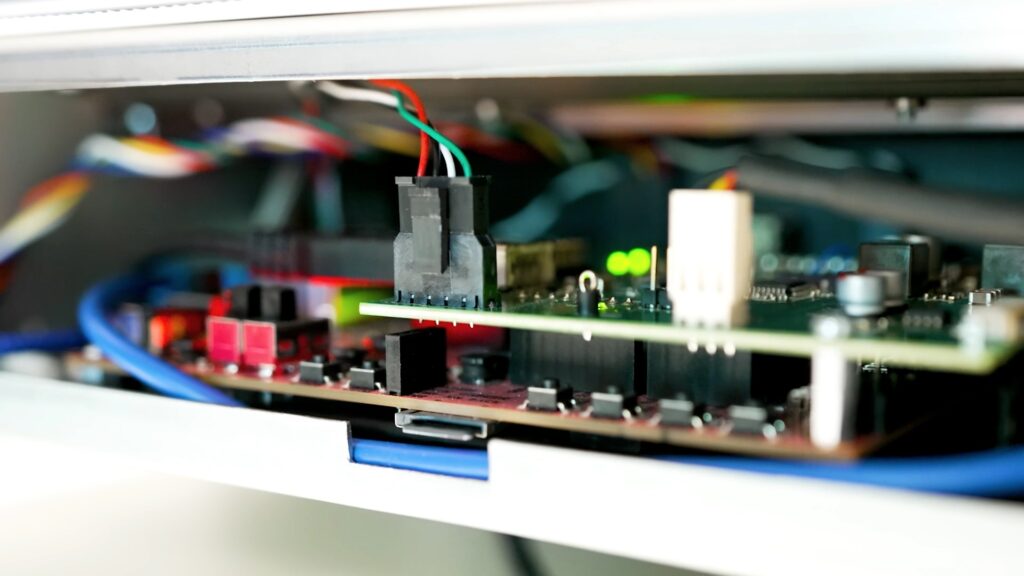

ELECTRICAL ENGINEERING

- Used standard off-the-shelf (OTS) boards when possible, reducing initial development investment and ensuring lower production costs.

- Developed four custom PCAs to address user interface electronics, wiper station motor function, carriage motor function, and a daughter board to the OTS board to increase functionality and customize the interface.

- Incorporated OTS cables and created 2 custom cables to allow for easy assembly, customized signal routing, and additional electrical properties needed for signal transmission.

- Developed each board with a custom bring-up test approach and checklist that was then transferred to ViewPlus to aid continued production.

- Captured and updated all board manufacturing documentation including schematics, layouts, block diagrams, and routing information based on feedback from the PCA manufacturers.

PROJECT MANAGEMENT

- Provided budget, schedule, and progress reports to ViewPlus.

- Confirmed that test procedures and results met product requirements.

- Coordinated tasks for all the team members to meet the client objectives.

- Scheduled and held meetings, took notes, assigned action items, and followed up on progress.

- Ensured that the project was completed on time and under budget.

“Working with Simplexity was an exceptional experience. They demonstrated an outstanding ability to grasp our objectives and provided the technical expertise, resources, and project management necessary to bring our vision to life. Their support allowed me to concentrate on my core competencies, confident in their handling of the technical and logistical aspects of our project."

— Dan Gardner, CEO, ViewPlus Technologies, Inc.

GENERAL PRODUCT DESIGN

- Designed the system with recurring cost and end-user sale price in mind.

- Quoted parts from multiple sources when possible, including suppliers already in use by the client.

- Evaluated molds and custom tools for long term production and cost impact prior to deciding on a manufacturing process.

- Designed the structure of the unit to optimize for how it may be carried and identified potential damage paths for the product prior to creating the final prototype.

- Provided input and fit results when evaluating the system for packaging designs.

THE RESULTS

The result of this engineering effort is a product that fully integrates with the ViewPlus embossers and increases the functionality of the print/emboss combination. This printer system allows for greater independence for visually impaired individuals while increasing the learning tools available in STEM fields.

By implementing LED and sound capabilities, this system can be operated by seeing and non-seeing personnel, making maintenance and updates easier for everyone.

This design has been created with future capabilities in mind including adding extra internal USB ports, leaving space on boards for future electronics, and allowing firmware updates to be made via an external interface. This allows ViewPlus to continue to grow the system with additional functionality with little or no impact on the overall design.

This product also allows for development of greater creative content for visually impaired individuals including games, puzzles, and other activities that were previously unavailable. This additional content and functionality continues to close the gap between the visually impaired and non-visually impaired individuals and will allow for more opportunities to learn, problem solve, and create!

If you are interested in learning more about ViewPlus, and want to discover the future of inclusive content creation, please check out their website, or email the CEO, Dan Gardner, to support their incredible work creating accessibility for all.

If you need help bringing a life-changing product to market, please contact us.