Case Study: New Matter 3D Printer

Before New Matter the company, there was just a guy with the notion that 3D printing was too complicated.

Steve Schell, a Caltech grad with strong ties to Idealab in Pasadena, California, felt strongly that the widespread adoption of 3D printers as a form of creative expression would require a major advancement in ease-of-use.

We met up with Steve Schell at a 3D printing conference in Burbank in late January, 2014 just after Idealab had funded his company, known at that time as IdeaShaper. Over lunch, Steve talked about his plan for creating not just a 3D printer, but an end-to-end solution for creative expression. He explained that the 3D printer would be affordable, would connect wirelessly to an online library of 3D files, and would come with user friendly software. It would be simple enough for anyone to use, even those with limited computer expertise. Steve wanted a 3D printer for ordinary folks, not just those immersed in hackerspace. If successful, the effort would create an entire community of users sharing 3D content and encouraging each other to explore creative expression. The online library would provide ordinary people with a place to share or sell their creative work. Interestingly, New Matter would later come to name the printer the MOD-t giving a nod to Henry Ford’s invention that democratized automotive technology.

We Were Intrigued

And so we began to follow the development effort with great interest. Early on, we learned that quiet printer operation would be important for successful home use. Imagine a noisy dishwasher running for 16-20 hours a day and you get the idea. Initially, the MOD-t used industry standard stepper motor drives common to most entry level 3D printers. With our expertise in inkjet printer development we recognized that DC servo motors could not only provide a quiet motion solution, but if implemented properly, could also improve dimensional accuracy during the build.

We presented a comparison of stepper motor technology to DC servo motor technology. While the development work would be more intensive for the DC servo motor solution the benefits were clear for this application.

“There are a lot of great 3D printers on the market, but most of them are either a. out of my price range (i.e the Formlabs Form 1), b. Loud and difficult to maintain (i.e RepRap) or c. both. Today I came across a printer that's neither. It's not perfect, but it's pretty damn great."

-geeky.io

DC Stepper Motor

Strengths

- Open loop positioning - no encoder required.

- High torque density at low speeds.

- Motor can be in a "stall" position without exceeding the temperature rating.

- Lowest cost solution.

Weaknesses

- No position correction in the event the load exceeds the output torque.

- Low power density - torque drops off dramatically at higher speeds.

- Motor draws continuous current, even at standstill.

- High iron losses at high rotational speeds.

- Noticeable cogging at low speeds. (can be improved with a micro-stepping drive)

- Ringing (resonance) at low speeds.

DC Brush Servo Motor

Strengths

- Linear speed / torque curve. (compared with a stepper)

- Low cost drive electronics. (4 power switching devices)

- Many different configurations available.

- Very smooth operation possible at low speeds.

- High power density - flatter torque at higher speeds. (compared with stepper)

Weaknesses

- Motor will draw high current in an overload condition.

- Encoder needed for closed-loop positioning. (same as the brushless motor)

- Brush wear.

- High terminal resistance. (copper is in the armature circuit)

“One of the great things about Simplexity is that their expertise is fairly wide ranging throughout the product development process. Their focus on the MOD-t project with New Matter was the embedded motion control system, the electronics design for the controller, and testing of that system as a whole.

It's great to have a partner like Simplexity who has so much expertise in electro-mechanical systems as well as embedded software because it bring so much capability to my engineering team in those really critical technology areas.”

-Steve Schell

CEO and Co-Founder, New Matter

Seamless Integration

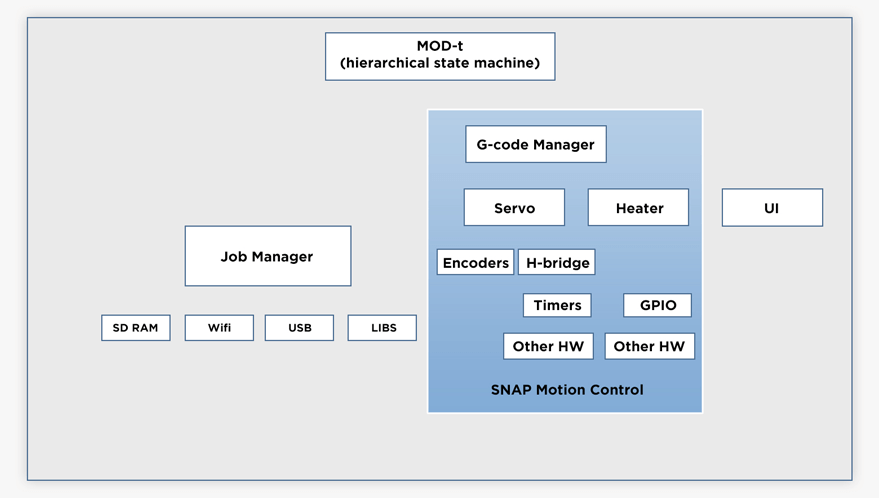

The next step was to figure out how Simplexity-developed motion control solutions could be integrated into New Matter’s development effort. Simplexity proposed a firmware architecture that would allow New Matter to focus on higher level programming tasks leaving the low-level motion control to us.

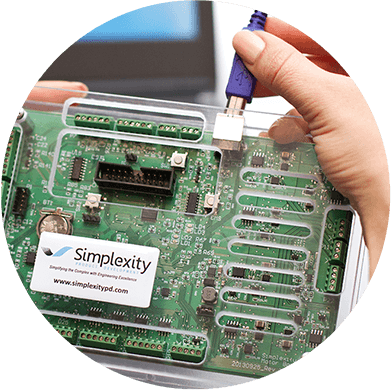

Simplexity's SNAP Mechatronics Board

The SNAP PCA provides general purpose two-axes motor control, numerous analog and digital I/O sensor interfaces, and a powerful ARM 32-bit Cortex-M processor. Development boards can be joined for applications involving more than two motion axes.

Impressive Results

The results are impressive. Working together, New Matter and Simplexity developed a technically superior 3D printer with quiet motion technology for under $400.

If you have a need for quiet motion technology whether as a standalone development kit, or as a fully embedded solution, contact us.