We recently returned from the 2025 Robotics Summit and Expo in Boston, MA. The event brings together over 5,000 developers focused on building robots for manufacturing, logistics, healthcare, aerospace, defense, and other markets.

Both Doug Harriman, VP of Engineering, and Scott Jarnagin, Director of Business Development, joined me at the summit to see the latest enabling technologies, engineering best practices, and emerging trends in Boston – the heart of robotics innovation.

Unitree Robot walking around the Robotics Summit

Four Quick Takeaways from the Robotics Summit

Tactile and Haptic Feedback

The buzz around emerging tactile and haptic technologies was exciting, especially since Simplexity has been working on some incredible client projects integrating and developing them both. With all the current hype, it can be easy to forget that providing a sense of touch feedback remains one of the greatest unsolved challenges in robotic manipulation. Many new companies, such as Contactile, ForceN, Xela Robotics, Ubiros and Liquid Wire are building solutions to tackle this at scale.

Humanoid Robots

We all know how fast AI is progressing, however the rise of humanoid robots in all environments is over hyped. Many industry experts indicate it will be 5-10 years before broader industrial adoption and 10+ years for home adoption due to sensing and manipulation challenges along with safety concerns.

AI

While AI is here to stay and will continue to evolve, AI is not the end-all, be-all. Many top companies still rely on traditional analysis and algorithm development when they can generate good analytical models. AI is the solution of choice when they can’t.

Hardware

Hardware reliability is critical to the effective industrial use of robots. Without capable hardware, robotic systems fail even with the most advanced AI. Connectors, sensors, motors, batteries and cables are critical to the reliability of these systems and good engineering still matters, A LOT!

Highlights from the 2025 Robotics Summit Keynote Speakers

There was a lot to see and do at the summit. From networking to vendors, we were busy making our rounds at the show, but our favorite activity was catching all the keynotes.

There were too many great speakers to highlight them all here, but the keynotes were packed with valuable takeaways.

Keynote: Redesigning Atlas: Boston Dynamics on the Future of Humanoids

Speaker: Aaron Saunders, CTO, Boston Dynamics

Aaron Saunders delivering a keynote

- Why the pursuit of humanoid robots? Declining populations and labor shortages along with different job preferences provide a ripe opportunity for advanced humanoid robots to participate in the solution space.

- When thinking of all the issues in challenging environments, such as navigating hazards and picking up complex components, no one piece of AI exists today to solve these problems.

- Unlike large language models, which are trained on abundant internet data, robots require physical interaction data—something that’s both scarce and difficult to collect. This lack of rich, scalable physical data presents a major obstacle to building robots that can generalize across real-world environments.

Keynote: The Future of Intelligent Automated Logistics

Speaker: James Kuffner, CTO, Symbotic

- Modeling physical systems, perception, control and physics are still incredibly important. Again, AI is not always the answer.

- Today, with a few exceptions, most robots only work in structured environments despite the many advances. AI advancements have helped move into unstructured environments.

- While AI can be thought of as “intelligence”, systems need experience or what he considers “artificial wisdom”, which relies on both traditional models of physical systems and AI.

Keynote: Inside the Evolution of Amazon’s Robots

Speaker: Aaron Parness, Director of Applied Science in Robotics and Artificial Intelligence, Amazon Robotics

Aaron Parness delivering a keynote

- Robotic vision systems alone can only get you 30% of the way there in solving complex picking problems. You need many other sensors including touch sensors to allow force feedback to get you to 90%, or more, when added with vision sensors. Aaron noted “Forces are the language of manipulation.”

- On the importance of building robust systems, Aaron pointed out that each Amazon fulfillment center handles over a million packages daily, meaning that even a “one in a million” error happens every day in every warehouse. These rare but inevitable issues must be resolved to avoid larger fulfillment issues.

- At Amazon they can’t fit the environment to the robotics. The robotics must adapt to the environment due to the scale of the operation.

- Manipulation is still mostly an unsolved challenge and giving robots a sense of touch unlocks a lot of opportunities.

Watch Vulcan, Amazon’s groundbreaking AI-powered robot equipped with a sense of touch

Keynote: Welcome to the Era of Physical Intelligence

Speaker: Daniela Rus, Director, MIT CSAIL

- AI is evolving from “saying” (chatbots), to “showing” (generative AI creating images and video), and now toward “doing” that is interacting with the physical world. By developing physics-based AI models, such as those at Liquid Networks, that are both energy-efficient and high-performing on smaller devices like robots, sensors, and smartphones, we can enable robots to become environmentally aware, causally grounded, and capable of acting as independent assistants to humans.

- Power to train AI is an enormous issue. Data centers will consume 5% of the US power generation in 2025, going to >11% in 2030

- Liquid Networks uses state space models at each neuron instead of simple sum and algebraic activation functions. Brings the recurrence into the neuron instead of requiring more neurons and synapses.

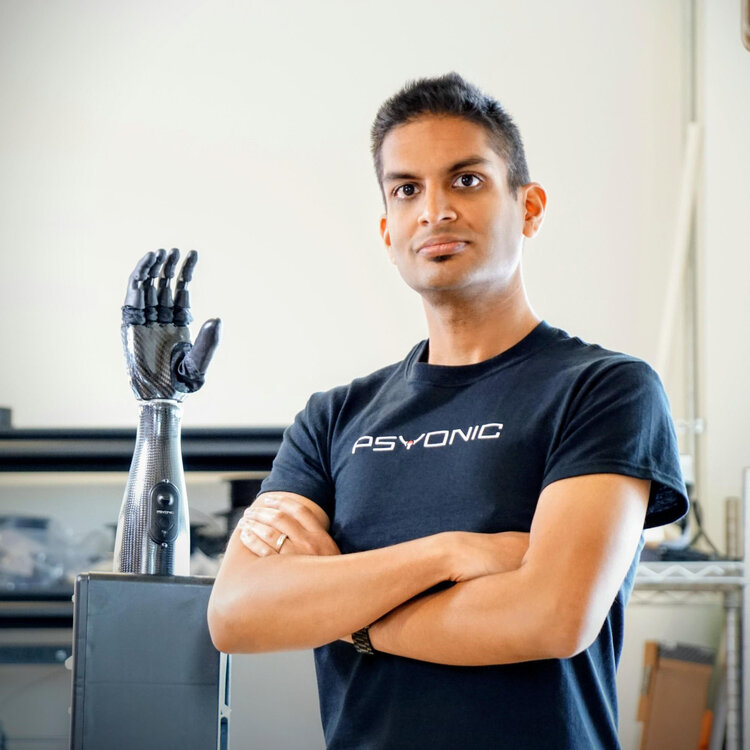

Keynote: Advanced Bionics for Humans & Robots

Speaker: Aadeel Akhtar, CEO & Founder, PSYONIC

- Developed the world’s first touch sensing bionic hand.

- The Ability Hand has integrated sensors that detect pressure when an object is gripped and sends a vibration to your arm to communicate the sensation.

- What struck me most is the journey of grit, determination, and steadfast alignment towards a single mission driven business.

Watch the world’s first touch-sensing bionic hand in action

Notable Tactile Sensing Companies at the Robotics Summit

In our industry, it is always valuable to keep up with the leading hardware providers focused on tactile sensing to enhance robotic manipulation.

Here are some notable companies developing tactile sensing technologies or supporting tactile sensing technology advancement at the show that grabbed our attention:

Contactile

State-of-the-art tactile sensors and grippers that enable intelligent robotic handling and manipulation for real-world applications.

ForceN

A Tier 1 provider of force-torque sensors and sensing intelligence for surgical, logistic and frontier robotics.

Liquid Wire

Leads the deformables market with electronics that maintain full functionality during movement and in any position (stretched, folded, etc.).

Ubiros

Fully electrically actuated soft grippers for food and beverage, cosmetics, and pharmaceuticals automation with certified food-grade fingers.

Xela Robotics

A hardware and software company specialized in tactile sensing technology, established to provide the human sense of touch to robots.

Unitree robot dog showing off some moves

2025 Robotics Summit and Expo Conclusion

The Robotics Summit was an informative, exciting event well worth the trip to Boston. We were happy to meet so many robotics enthusiasts and get a chance to see a lot of cutting-edge technologies packed into two days.

With the wrap of this year’s Robotics Summit, we are excited to announce that we will be exhibiting at the upcoming RoboBusiness show (also produced by WTWH Media) in Santa Clara, October 15th and 16th. We hope you will join us at booth 712 while we get ready for all the robotics action on the West Coast.

Resources:

- CNBC: Amazon says new warehouse robot can ‘feel’ items, but won’t replace workers

- The Robot Report: Amazon’s Vulcan robot uses force sensing to stow items

- The Robot Report: Recapping Robotics Summit & Expo 2025