Simplexity Product Development joined the ARM (Advanced Robotics for Manufacturing) Institute in 2024. The ARM Institute is funded by the U.S Department of Defense (DoD) as a Manufacturing Innovation Institute and is entrusted to lead the future of robotics in manufacturing in the United States.

Simplexity VP of Engineering, Doug Harriman, and I attended the ARM Institute annual member meeting in Pittsburgh, PA from Sept. 23rd to 25th, 2024.

Simplexity CEO, Dorota Shortell, and VP of Engineering, Doug Harriman at the 2024 ARM Institute member meeting

See below for some of the main insights we gathered from the member meeting.

Artificial Intelligence

Artificial Intelligence (AI) is a buzzword in many industries today and this includes robotics. During the meeting new member organization were asked to give a 5-minute pitch about their organization. Below are a couple of interesting ones that are using AI for advancements in robotics:

-

- ThoughtForge AI – Creates software that help robots proactively predict, infer, and react accurately to changes in their environment in real-time.

- Altitude AI – Have created a software tool to help humans easily and intuitively program robots to perform complex tasks without learning complex programming languages and environments.

AI is blurring the lines of what will be needed from the robotics industry. There was much discussion on where AI can be useful for advancing robotics adoption and integration and where traditional automation is sufficient. It’s important to separate the AI hype from the applications where AI is providing a real benefit. A lot of the focus will be in using AI to address the gaps in specific use cases rather than using AI as a tool for every scenario. Sometimes traditional automation that is already used in the robotics industry is sufficient and more reliable, let alone well proven.

While Simplexity is not an AI company, we do develop hardware for AI and software companies. To learn more about AI-related projects that we’ve done, check out AI Hardware Development.

The Need for Robotics Integrators

ARM Institute’s Chief Operating Officer, Jay Douglass, outlined key statistics about the institute, which is made up of a consortium of over 400 organizations. One of the areas they had identified in past years was not enough companies who can serve as integrators of robotics, helping manufacturers who would like to add robotics to automate their production line or processes. He was pleased to report that over 10 new robotics integrators had joined ARM, of which Simplexity was included.

As a new member company, my 5-minute pitch about Simplexity focused on the work that we’ve done implementing robotics for various industries, including several case study projects. You can read more and find videos on Simplexity’s Robotic Product Development page. Simplexity is currently working on several robotics integration projects.

Simplexity CEO Dorota Shortell presenting Simplexity’s robotics integration and custom design projects to the ARM Institute audience

Robotics Market Trends

Alex Shikany, Vice President of Membership & Market Intelligence at the Association for Advanced Automation (A3), gave a comprehensive overview of the robotics market. Some of the highlights are below.

- Purchases of robotic arms and systems peaked in 2022 as was the case with many products after the pandemic induced supply chain crisis. While orders have been lower in 2023 and 2024 than in 2022, they are returning to pre-pandemic levels. Overall Alex is bullish on the market since we are still in the early days of robotic adoption, new industries are emerging, and labor shortages are making automation necessary.

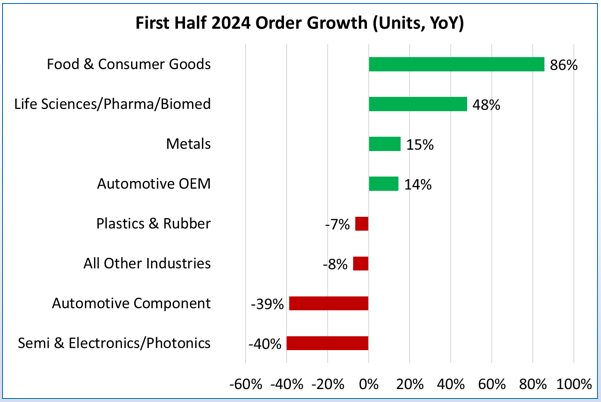

- During the first half of 2024, robot orders have grown considerably in the Food & Consumer Goods and the Life Sciences, Pharma, and Biomed industries. Orders have fallen in the Automotive Component and Semi & Electronics/Photonics industries.

Statistics showing robot order growth or decline by industry in the first half of 2024, courtesy of Alex Shikany of the Association for Advanced Automation (A3)

The four markets that are expected to see the most growth of robotics and automation in the future include;

-

- Hospitals – robots that take over the mundane tasks like logistics for nurses so they can focus more of their time on patient care.

- Agriculture – robots that automatically weed and seed among other tasks. While not featured during the meeting, Simplexity has worked on robots for this industry, such as a robotic plant health monitoring system.

- Construction – robots that help build houses, such as the HadrianX construction robot. This should be good tidings for Dusty Robotics, a Simplexity client who has developed a robot that automatically prints construction drawings on the slab.

- Textiles – automated garment production has been a huge focus as it is a trillion dollar industry. The US only generates 3% of worldwide clothing production, but purchases 27% of worldwide output. Companies like Henderson Sewing, Apparel Robotics, and Sewbo are working together with other ARM member companies on new methods for automating clothing production using robotics. Simplexity also has experience in soft goods robotic automation.

- In addition, I enjoyed meeting a new startup, Seamly Systems, who has taken a CAD approach to clothing design, which, as a mechanical engineer, I absolutely love. They are looking to revolutionize the fashion industry via their universal sizing solution.

- In addition to garments, there is extensive work going into other sewn goods such as personal protection equipment (PPE), automotive interiors, temporary shelters (i.e. tents, awnings), and inflatables such as air bags and flotation devices.

Other Interesting Findings

Beyond the key trends I found at the meetings, there are some other items of interest that I believe are worth sharing.

Robotic Demos and Interesting New Entrants

There were multiple companies exhibiting at the meeting, so it was great seeing the technology first-hand. There are too many to list here, but some of the notable ones were:

- Medema Labs – an Oregon company that helps product designers determine the best manufacturing methods and processes for their parts via automated virtual tools.

- ARM Institute – ARM hosted a reception and demo at their location, a converted steel mill. They have demos and a learning center including 12 different robotic cells. I took a quick video of one of them

Robot demo at ARM Institute’s Pittsburgh headquarters

- Haptx – I was drawn to their table, since they are using a Valve virtual reality (VR) headset, which Simplexity helped design (see Valve Index). Haptix has developed a haptic gloves for use in VR applications. I put a pair on along with the VR headset to see how they work. The VR demo included picking up things like spiky balls, flopping fish, shells, and even bouncing balloons. The demo felt very life like, although I have to admit that I am hardly a super user and kept dropping the virtual items!

Simplexity CEO Dorota Shortell experiencing the feeling of haptic gloves from Haptx

BONUS – while they weren’t at the ARM meeting, we did get a personal tour of Carnegie Robotics, a successful privately held robotics company in Pittsburgh. Carnie Mellon University has served as a catalyst for the Pittsburgh area to develop quite the robotics hub, with over 100 robotics companies in the area. My favorites from the tour were an autonomous floor scrubbing robot and a mine sweeping robot. I learned that the optimal speed for sweeping mines is 1 meter per MINUTE – that’s right, think about how painfully slow it would be walk at that pace while fretting that you may be encountering a live mine. Much better to have a robot do that work!

Additional Robotics Events

If you’re interested in attending shows and events in the robotics industry, here are a few on the horizon:

- Jan 2025: A3 Business Forum in Orlando, FL

- April 2025: Robotics Summit & Expo in Boston, MA

- May 2025: Automate in Chicago, IL

- Sept 2025: next ARM Institute Annual Member Meeting in Pittsburgh, PA

Finally, if you’re looking for a job in robotics, check out RoboticsCareer.org, powered by the ARM Institute.