CASE STUDY: AIVOT

General-purpose and fast-learning robots built to multiply your workforce for a fraction of the cost of labor

![]()

THE CHALLENGE

Aivot is a robotics company developing helper robots that perform simple tasks across a broad range of applications such as home use, manufacturing, hospitality, food preparation, and service applications.

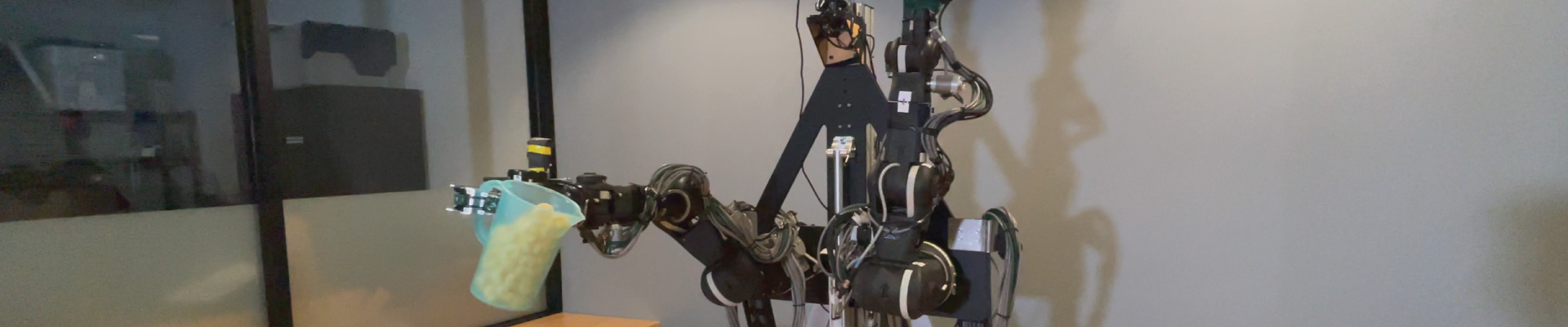

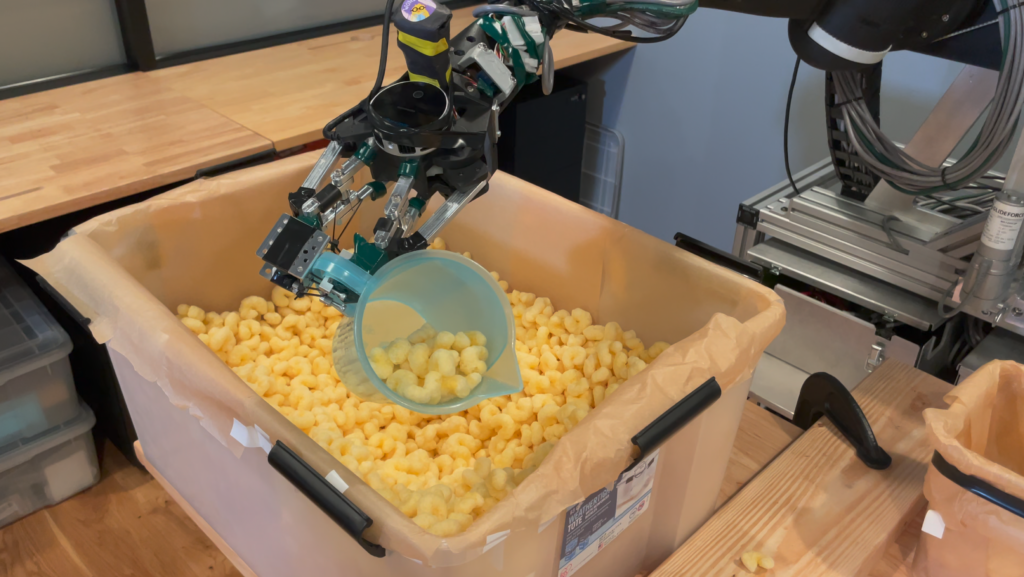

The robot can either be programmed via the User Interface (UI) or directly trained by the user who shows the robot a task which is captured by the vision system. Aivot’s proprietary algorithm then applies the task recording to have the robot mimic what it saw via the vision system. Once trained, the robot can easily reproduce the tasks, eliminating the need for humans to manually perform menial day-to-day tasks. The algorithm has been shown to work in simulated environments as shown in the video below with Aivot founder and CEO, Shashwat Srivastav.

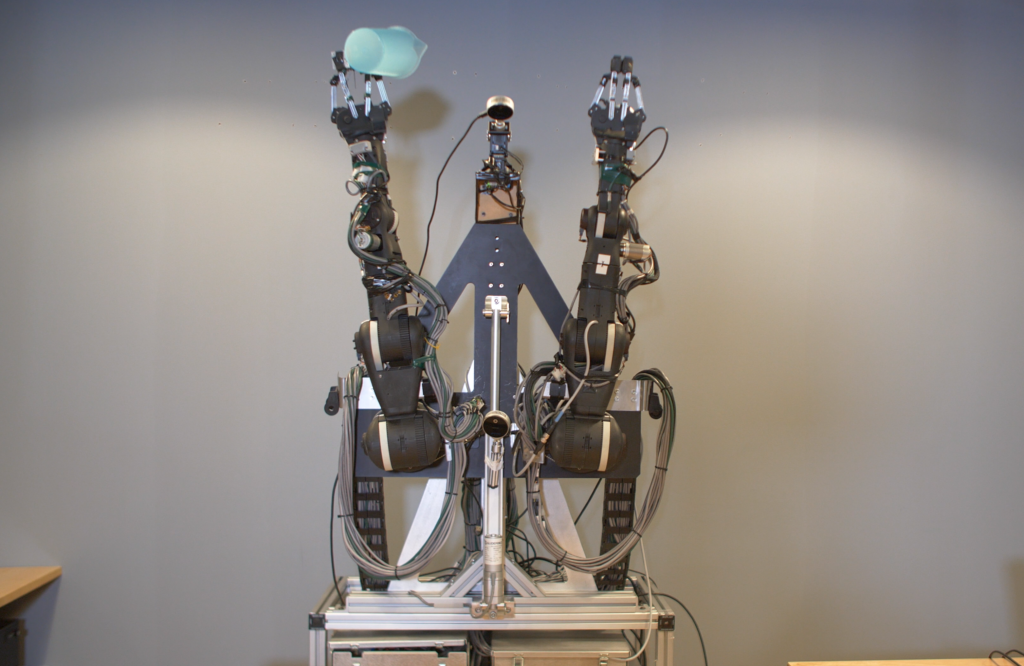

The full hardware system is composed of:

- Two 6-degree of freedom (DoF) arms

- A mobile base

- A motorized gimbal capable of pitching and yawing the vision system

- A z-lift mechanism capable lifting the arms and vision system

The resulting robot is capable of moving between locations and manipulating physical items at heights from the floor to shelves 6+ feet high.

THE SOLUTION

Aivot approached Simplexity to develop the robotic hardware to be used to demonstrate viability of their software while targeting a cost structure of a consumer product. They had a solid software development team in-house but needed a partner to assist with hardware and systems engineering.

As a startup, Aivot had a limited development budget. Therefore, Simplexity’s mechanical and systems engineers approached this project with a determination to minimize development cost while still delivering a system that would meet the client’s technical needs.

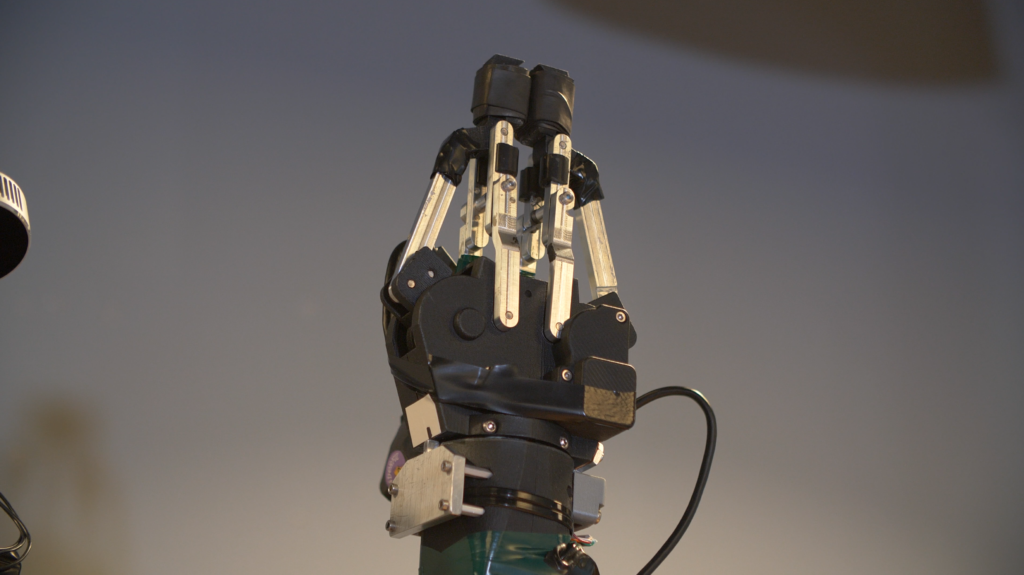

Utilizing open-source mechanical design as a basis for the arm, a system capable of the control and performance requirements was developed. Simplexity worked closely with Aivot to design a gripper capable of picking up a variety of objects that the robot can expect to see in use around the home. The grippers were fitted to the arms which were then installed on a custom wheeled frame that was pushed around by a mobile base. The resulting system consists of 2 arms capable of reaching from the ground to 6 feet high, thereby enabling completion of many different user tasks, safely in close proximately to humans.

The two arms were attached to a vertical motion stage which was mounted on the frame and attached to the mobile base. Simplexity engineers were very cognizant of how the robot was going to be used, basing the maximum dimensions of the robot such that it could fit through the smallest standard sized door.

“I’d highly recommend Simplexity to a friend. They have good expertise in what they do, they’re great partners, and they deliver projects on time, within budget, and with great results.”

- Shashwat Srivastav

Founder and CEO, Aivot

APPLICATIONS

The Aivot robot has many areas where it could benefit end-users. Using their novel algorithm, the system could be used for a wide range of applications:

- Home - Reproduce tasks of people around their homes, helping them increase their personal productivity by eliminating menial tasks.

- Service Industries - The robot will be able to reproduce tasks such as cleaning equipment or prepping food in a restaurant. This can reduce financial overhead of a company by reducing the labor costs of operation.

- Manufacturing - Manufacturers could eliminate multiple machines by providing this as a platform solution capable of learning and adapting to different tasks that the company needs.

- Hospitality - the robot could be used to help with housekeeping tasks like towel collection, bed making and minibar replenishing.

RESULTS - HOW DID THE CLIENT BENEFIT?

Smaller clients, especially start-ups, benefit greatly by partnering with design focused product development companies that specialize in complex multi-disciplinary systems designs. Simplexity provided a large and diverse engineering team to the client, much faster and more cost effectively than one could be built internally. Because of Simplexity’s capabilities, the project:

- Met the size and performance specifications

- Met the short time horizon needed for the company to continue development; Included coordination with Aivot to send interim development tools to facilitate faster integration of the system.

- Provided a full featured solution that is cheaper than current alternative market options.

- Provided a path to future cost reductions as the product moves towards commercialization

- Allowed Aivot to remain focused on their core competency, algorithm development, without the distraction of trying to build a hardware design team.

Simplexity’s design met the client’s required performance for the first phase of development while staying within the required schedule and budget. Simplexity provided a hardware system that allowed Aivot to further algorithm development. This allows Aivot to demonstrate their technology in real-time to potential investors and customers. Once the use cases and technology are proven, then Aivot can complete the next phase of development to bring many of these robots to market, helping to eliminate repetitive tasks for humans and bring down labor costs.

WATCH THE AIVOT AI ROBOT IN ACTION PERFORMING TASKS!

Food Assembly

Food Packaging

Kitchen

Logistics

Shopping