Product Development Process

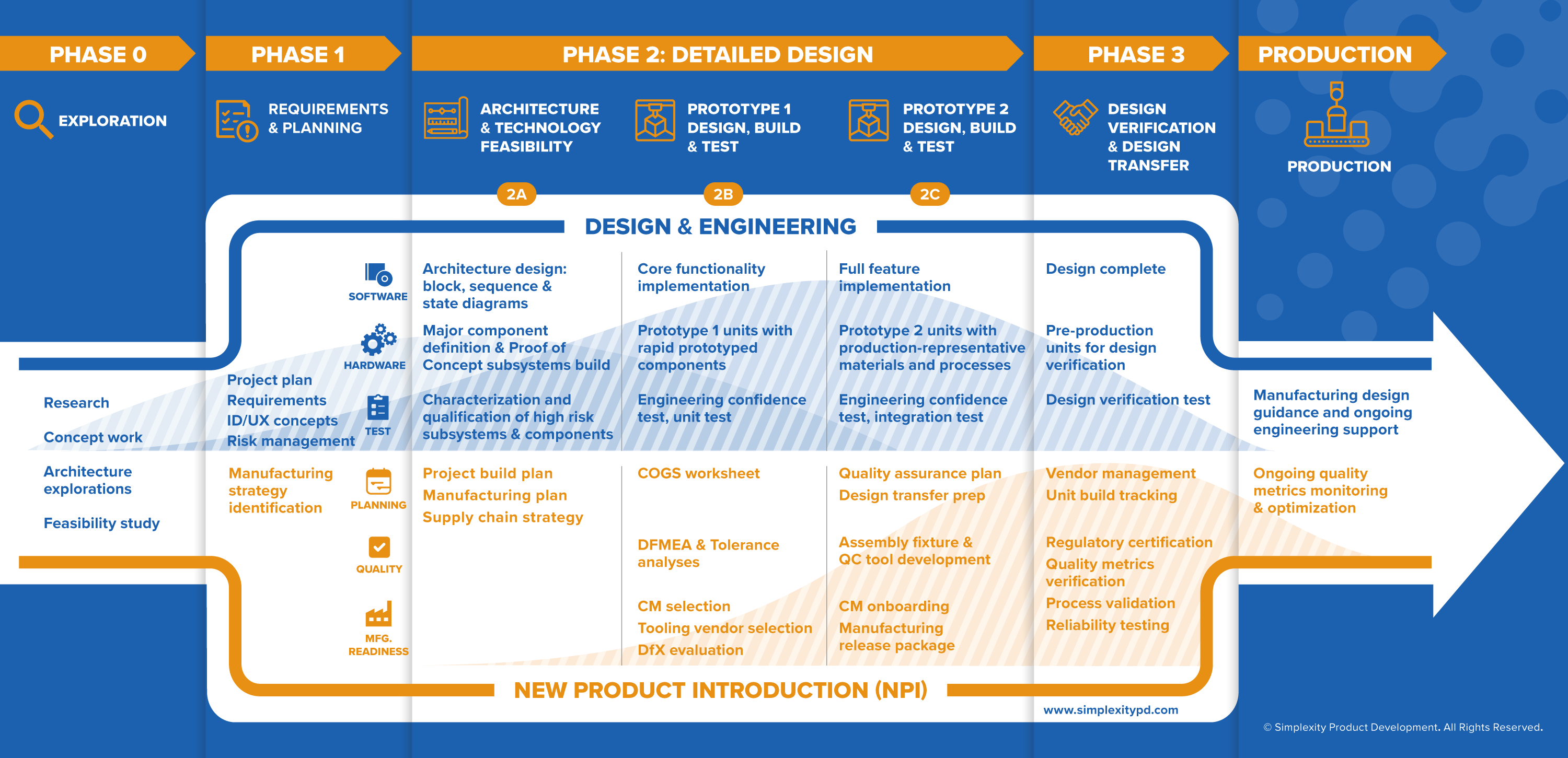

Simplexity uses a phase-gate process, based on decades of experience and industry best practices, to guide our product development process. Design is an iterative process, whereby unknowns and high-risk areas are best resolved through exploration and analysis, building prototypes and testing as early as possible.

The Phases of Product Development

Our approach is to identify the highest risk aspects of a product and devise effective ways of assessing those risks, usually through different levels of prototyping and analysis.

Phase 0: Exploration

Exploration

Research

Concept Work

Architecture explorations

Feasibility studies

Phase 0 is an optional phase for projects where the technical feasibility of the idea has not yet been fully proven. It can consist of research, concept work, exploring initial architecture, performing feasibility studies, and basic prototyping and testing.

Typical deliverables:

- Exploration report

Gate definition:

- Client approval on feasibility of idea

Phase 1: Requirements & Planning

Design & Engineering

Project Plan

Requirements

ID/UX Concepts

Risk Analysis

NPI

Manufacturing Strategy Identification

The business and user requirements are converted into engineering requirements for the product. The project planning activity is based on the schedule, budget, risk, and initial product requirements. This process is best done as a collaborative team effort with the client, who has the deepest understanding of the market needs and user requirements.

Typical deliverables:

- Product requirements document

- Manufacturing strategy requirements document

- Project development plan (including plans for software/firmware electrical, quality, systems, and mechanical)

- Risk analysis

- Industrial Design (ID) and User Interface (UI) concepts

Gate definition:

- Product requirements document complete

- Client approval of project development plan

Phase 2: Detailed Design

Design & Engineering

Software: Architecture design: block, sequence and state diagrams

Software: Architecture design: block, sequence and state diagrams

Hardware: Major Component definition & Proof of Concept subsystems build

Hardware: Major Component definition & Proof of Concept subsystems build

Test: Characterization and qualification of high risk subsystems & components

NPI

Planning: Project build plan, Manufacturing plan, Supply chain strategy

Planning: Project build plan, Manufacturing plan, Supply chain strategy

2A. Architecture and Technology Feasibility

The detailed design phase starts with defining options for the product architecture, with the goal of having the greatest chance of successfully meeting product requirements while best mitigating risk. Engineering activities in this phase include presenting options for hardware components, outlining the system block, sequence, and state diagrams, creating rough CAD, and breadboarding of high-risk subsystems. Results are presented with a description of the pros, cons, and key tradeoffs for each scenario.

Typical deliverables:

- System architecture design (including mechanical, electrical and software/firmware)

- Initial product risk analysis

- Breadboards or proof-of-concept prototypes of high-risk technologies or subsystems.

- ID concept models

- Manufacturing processes review

- Product requirements review

- Critical Performance Metrics (CPM) specifications review

- Project build plan

- Manufacturing plan

- Supply chain strategy

Gate definition:

- Client approval following hardware and software architecture reviews

Phase 2B: Detailed Design

Design & Engineering

Software: Core functionality implementation

Software: Core functionality implementation

Hardware: Prototype 1 units with rapid prototyped components

Hardware: Prototype 1 units with rapid prototyped components

Test: Engineering confidence test, unit test

NPI

Planning: COGS worksheet

Planning: COGS worksheet

MFG. Readiness: CM selection, Tooling vendor selection, DfX evaluations

MFG. Readiness: CM selection, Tooling vendor selection, DfX evaluations

Quality: DFMEA & Tolerance analyses

Quality: DFMEA & Tolerance analyses

2B. Prototype 1 Design, Build And Test

The detailed design phase usually has multiple, iterative sub-phases as the design progresses and representative prototypes are built. Phases 2B and 2C are typically the largest efforts in the product development process, where the specific implementation for all disciplines occurs (mechanical, industrial design, electrical, firmware, systems, software, manufacturing, and quality).

Simplexity typically engages with production component suppliers and contract manufacturing groups early in this phase to provide additional DfX evaluations on manufacturing, assembly, and serviceability of the design. Contract manufacturing and tooling vendors are selected in this phase and initial costing estimates are prepared. Our quality team performs DFMEA and tolerance analyses and, if the product has stringent testing or certification requirements, pre-screens are performed in this phase prior to formal regulatory agency testing.

Typical deliverables:

- Prototypes (3D printed or other rapid prototypes, electrical PCAs, and/or preliminary code)

- Software and hardware design documentation

- Initial product firmware or software binaries and source code

- Electrical schematics and layout

- 3D CAD files

- Cost of Goods Sold (COGS) worksheet

- RACI chart

- Subassembly strategy development

- Process flow documents

- Test plans and reports

- Design failure mode and effect analysis (DFMEA)

- Tolerance analysis

- DfX Evaluations (for manufacturability, assembly, and serviceability)

- Test plans and reports

- Contract Manufacturer (CM) quote package and selection

- Tooling vendor selection and schedule

Gate definition:

- Engineering confidence test reviews

Phase 2C: Detailed Design Prototype 2

Design & Engineering

Software: Full feature implementation

Software: Full feature implementation

Hardware: Prototype 2 units with production-representative materials and processes

Hardware: Prototype 2 units with production-representative materials and processes

Test: Engineering confidence test, integration test

NPI

Planning: Quality assurance plan, Design transfer prep

Quality: Assembly fixture & QC tool development

Quality: Assembly fixture & QC tool development

Mfg Readiness: Manufacturing release package, CM onboarding

2C. Prototype 2 Design, Build And Test

Phase 2C iterates on the learnings of Phase 2B and involves a refined prototype build of a fully integrated system. Some projects also benefit from additional iterations of the product based on prior learnings through additional phases (2D, 2E, etc), which are not represented in this graphic. All requirements are intended to be tested, and at the end of Phase 2 there will be confidence that the units will pass verification in Phase 3. The Bill of Materials is further refined, and the team updates estimates for the per unit cost of the product by receiving pricing from vendors and suppliers.

Typical deliverables:

- Updated prototypes

- Software and/or firmware binaries and source code

- Updated schematics and layout

- Updated 3D CAD files and 2D drawings

- Design transfer preparation

- Contract Manufacturer onboarding

- FAI and first article reports

- Quality assurance plan

- Manufacturing release package

- Assembly fixture & QC tool development

Gate definition:

- Engineering confidence test reviews (integration tests)

Phase 3: Design Verification And Design Transfer

Design & Engineering

Software: Design Complete

Software: Design Complete

Hardware: Pre-production units for design verification

Hardware: Pre-production units for design verification

Test: Design verification test

NPI

Planning: Vendor management, Unit build tracking

Planning: Vendor management, Unit build tracking

Quality: Quality metrics verification, Process validation, Regulatory certification, Reliability Testing

This phase occurs once the detailed design is complete, and prototypes are built with manufacturing-representative quality and detail. More extensive, formal testing is performed, such as life, reliability, safety, environmental, drop, and vibration.

The design team works closely with the manufacturing team to enable a smooth transfer, often with Simplexity engineers traveling to the contract manufacturer sites to ensure product quality. The design is transferred to the client based upon specific needs, most often after all tests are complete and the design is verified.

Typical deliverables:

- Pre-production units

- Formal verification test reports

- Design transfer package, including Design History File (DHF) if needed for FDA submittal

- Process validation support

- Unit build tracking

- Quality metrics verification

- Vendor management

- Root Cause Analysis (RCA) Defect Resolution

- Regulatory certification

- Reliability testing

Gate definition:

- Design verification complete

Production

Design & Engineering

Manufacturing design guidance and ongoing engineering support

NPI

Ongoing quality metrics monitoring & optimization

The Simplexity team can be as involved in the production phase as requested by our clients. For clients with internal manufacturing or established relationships with contract manufacturers, our engineers are available to ensure quality is maintained and provide ongoing engineering support as needed.

Simplexity has a dedicated New Product Introduction (NPI) team that can guide the transition from design into production. The NPI team presents multiple options for manufacturing to the client, allowing clients to choose the solution that best suits their needs. This can involve Simplexity performing initial builds in-house prior to full handoff to a contract manufacturer or building the product via established relationships with contract manufacturing partners either domestically or overseas early in the process.

Typical deliverables:

- Manufacturing guidance and ongoing engineering support

- Ongoing quality metrics monitoring and optimization

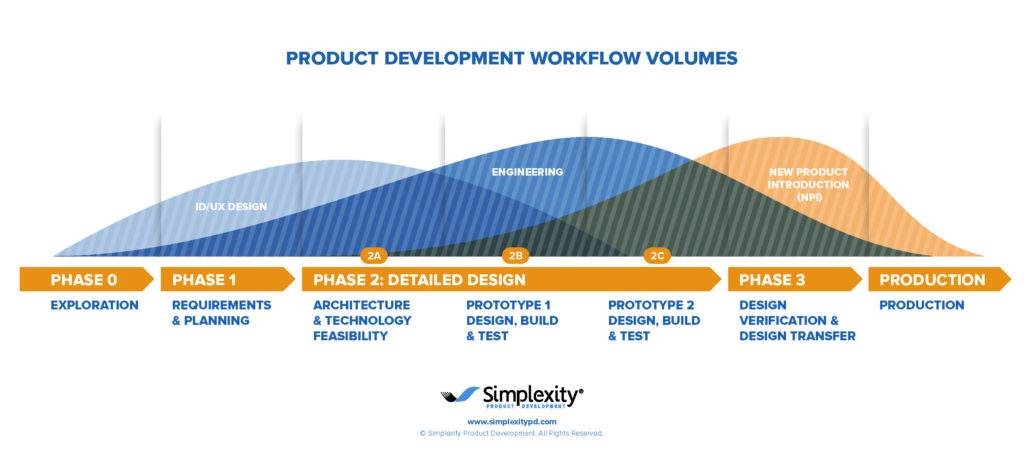

Product Development Workflows

The diagram below indicates typical workflow volumes that relate to each of the Phases described above for ID/UX design, engineering and New Product Introduction (NPI)