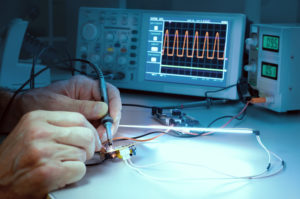

Artificial Intelligence (AI) is rapidly proving its value in electrical engineering by automating repetitive tasks, improving efficiency, and providing quick access to relevant data. Another strength is its ability to… Read More

HOW AI CAN IMPROVE THE ELECTRICAL ENGINEER’S WORKFLOW