Embedded systems are in millions of products that we use every day. It’s easy to take it for granted that I can unlock my front door from my phone while… Read More

IMPORTANT CONSIDERATIONS FOR DEVELOPING A SECURE EMBEDDED IOT PRODUCT

| by Katie Elliott

Embedded systems are in millions of products that we use every day. It’s easy to take it for granted that I can unlock my front door from my phone while… Read More

| by Tristan Dudik

My wrists were naked from 2005 to 2019. It was 2005 that I got my first cell phone, a flip phone with a secondary display which displayed the time on… Read More

As we get ready to bid 2022 farewell, we reflect on 5 market trends driving engineering design development into the future. One of the truly great pleasures of working at… Read More

| by Katie Elliott

Power management is an important concern when dealing with small, battery-powered devices such as sensors or wearables. The successful design of low-power devices requires a concerted team effort between the… Read More

In a quest to feel connected while quarantined, Augmented Reality (AR) and Virtual Reality (VR) can offer a great way to connect with family, friends, and of course collaborate with… Read More

Staying connected in a post-COVID-19 world is a challenge we are all facing together. But never has it been easier to use technology such as Augmented Reality (AR) and Virtual… Read More

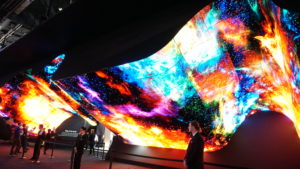

With over 4,500 companies touting their latest and greatest products, CES 2020 was a blast. We are certainly glad we made it to this impressive technology-driven event, one of the… Read More

| by Gabriel Aldaz

In this blog post we will explore two audio receivers, which are a stereo system’s control center for audio and video sources. Specifically, we will compare a Beomaster 1900 receiver,… Read More

| by Scott Jarnagin

It’s that time of year again! After the empty boxes, empty calories, and the holiday lights have come down, it’s time for the tech-loving adults to enjoy their annual after… Read More

| by Kristin Pollock

PLAYING THE ROLE OF ‘CUSTOMER’ Ossia is building a system which will allow for truly wireless power – without charging cables or pads. They license their technology to companies creating the… Read More

The Simplexity team can be as involved in the production phase as requested by our clients. For clients with internal manufacturing or established relationships with contract manufacturers, our engineers are available to ensure quality is maintained and provide ongoing engineering support as needed.

Simplexity has a dedicated New Product Introduction (NPI) team that can guide the transition from design into production. The NPI team presents multiple options for manufacturing to the client, allowing clients to choose the solution that best suits their needs. This can involve Simplexity performing initial builds in-house prior to full handoff to a contract manufacturer or building the product via established relationships with contract manufacturing partners either domestically or overseas early in the process.

This phase occurs once the detailed design is complete, and prototypes are built with manufacturing-representative quality and detail. More extensive, formal testing is performed, such as life, reliability, safety, environmental, drop, and vibration.

The design team works closely with the manufacturing team to enable a smooth transfer, often with Simplexity engineers traveling to the contract manufacturer sites to ensure product quality. The design is transferred to the client based upon specific needs, most often after all tests are complete and the design is verified.

Phase 2C iterates on the learnings of Phase 2B and involves a refined prototype build of a fully integrated system. Some projects also benefit from additional iterations of the product based on prior learnings through additional phases (2D, 2E, etc), which are not represented in this graphic. All requirements are intended to be tested, and at the end of Phase 2 there will be confidence that the units will pass verification in Phase 3. The Bill of Materials is further refined, and the team updates estimates for the per unit cost of the product by receiving pricing from vendors and suppliers.

The detailed design phase usually has multiple, iterative sub-phases as the design progresses and representative prototypes are built. Phases 2B and 2C are typically the largest efforts in the product development process, where the specific implementation for all disciplines occurs (mechanical, industrial design, electrical, firmware, systems, software, manufacturing, and quality).

Simplexity typically engages with production component suppliers and contract manufacturing groups early in this phase to provide additional manufacturing input on the design. If the product has stringent testing or certification requirements, pre-screens are performed in this phase prior to formal regulatory agency testing.

Phase 0 is an optional phase for projects where the technical feasibility of the idea has not yet been fully proven. It can consist of research, concept work, exploring initial architecture, performing feasibility studies, and basic prototyping and testing.

The business and user requirements are converted into engineering requirements for the product. The project planning activity is based on the schedule, budget, risk, and initial product requirements. This process is best done as a collaborative team effort with the client, who has the deepest understanding of the market needs and user requirements.

The detailed design phase starts with defining options for the product architecture, with the goal of having the greatest chance of successfully meeting product requirements while best mitigating risk. Engineering activities in this phase include presenting options for hardware components, outlining the system block, sequence, and state diagrams, creating rough CAD, and breadboarding of high-risk subsystems. Results are presented with a description of the pros, cons, and key tradeoffs for each scenario.