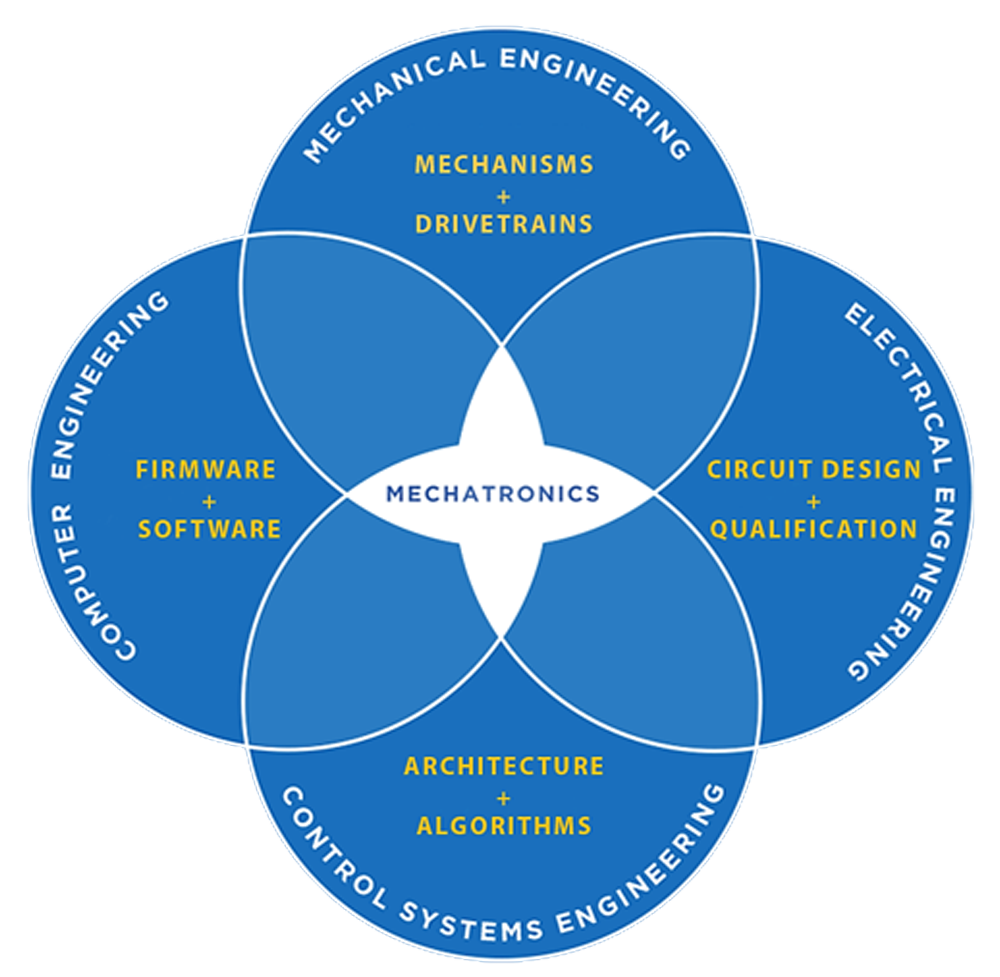

The word “mechatronics” was first coined in Japan in the late 1960’s to refer to the synergistic blend of mechanics and electronics. The word has evolved to describe products and systems that include not only mechanics and electronics, but the software in the electronics, and the control algorithms in that software. Mechatronic systems encompass many of the products we deal with every day, especially those that interact with the physical world. Planes, cars, printers, automatic coffee makers, computer hard drives, production line automation and even robots are all examples of mechatronic systems.

Clip: Embedded FM Podcast

It’s hard to build a mechanical system these days without some electronics. Adding electronics and “smarts” is the clear path to increase performance and decrease cost in many products. However, it’s important that a product be more than just an amalgam of plastic, metal and circuits. Products designers must consider the whole instead of just the individual pieces. To harness the power of integrating the technologies, the system must be designed from the start as an integrated mechatronic product.

Because of the performance and cost advantages delivered in high quality mechatronic systems, the term has morphed from just describing the systems themselves, into a word that is applied to the design process itself.

“Mechatronics is really all about design of any physical system, where you integrate controls, electronics, and computers from the very start of the design process.” ~Prof. Kevin Craig, Marquette University.

As a very simple example of what happens when you don’t design with a mechatronic focus, I will relate a story about a copier design in which I participated. Like many product development projects, the traditional disciplines of mechanical, electrical and software engineering were in siloes, working mostly independently. In this copier, there was a condition where a motor in the scanner subsystem could accelerate at the same time as a motor in the printer subsystem. The electrical engineer, working diligently in his silo, increased the size of the power supply to deal with this maximum power draw. This added significant cost to the system. Because I came in from the outside, I was able escape the traditional silos and take a mechatronic approach to the problem. I created a simple algorithm that slightly delayed the start of one of these motors when the other was already accelerating. This greatly reduced the system peak power, and allowed the use of a much cheaper power supply. This is a simple example, but shows the power of considering the whole system instead of just the individual parts.

To design truly excellent products, those that both out-perform and cost less than the competition, highly integrated mechatronic designs are crucial. Companies that have a strong mechatronic design team will outperform those that have teams separated by traditional engineering discipline. This final quote sums it up nicely:

“That’s because innovation often happens not in the center of a discipline but in the space between disciplines…” ~Harry West, The Cross-Discipline Design Imperative, BusinessWeek Online

YOU MAY ALSO LIKE: