Artificial Intelligence (AI) is rapidly proving its value in electrical engineering by automating repetitive tasks, improving efficiency, and providing quick access to relevant data. Another strength is its ability to surface insights that might otherwise be overlooked, whether by spotting patterns across large datasets or by summarizing information buried deep in technical documents.

I’ve personally used AI to:

- Create technical documents

- Write Python scripts for data analysis and plotting

- Generate practical checklists—such as preparing my pickup and 5th-wheel trailer for towing—impressing me with its thoroughness and accuracy

As AI matures, specialized tools are emerging to streamline engineering workflows, from schematic checking to design-for-manufacturing (DFM) and design-for-assembly (DFA) analysis. While AI can’t replace an engineer’s judgment, it can handle much of the groundwork, leaving engineers free to focus on high-impact decisions.

Why AI Fits Naturally into Engineering

AI has access to the same types of resources that engineers use—datasheets, component databases, specifications, and books—but it can search, parse, and summarize this information much faster.

- What AI does well: Performing defined, structured tasks

- What AI cannot yet replace: Engineering judgment and creative problem-solving

Engineering Tasks Enhanced by AI

1. Project Setup

Schematic tools like OrCAD X and Altium require entering parameters used across multiple design stages. AI can generate Python or Delphi scripts to automate this process, ensuring consistency across projects and teams.

2. Requirements Gathering

Marketing teams often provide high-level customer requirements, but engineers need detailed, actionable design requirements. AI can extract relevant technical details from lengthy documents—such as safety standards—saving engineers hours of manual review.

3. Design Architecture

AI can help define architecture and generate block diagrams from provided parameters, offering a solid foundation for further engineering work.

4. Circuit Design and Schematic Generation

- Generate functional block schematics (e.g., amplifiers, filters)

- Provide functional equations and discrete component values

- Create pin lists and descriptions from datasheets for schematic symbol creation

Tools:

– SnapMagic works within your schematic capture tool and provides component search capabilities, integrates component into schematic along with support components and traces, and provides availability and costing information for filling out the BOM, all in one AI tool.

– Circuit Mind provides component search abilities, and can generate schematics around the selected component automatically.

5. Component Selection

Given specific parameters, AI can search manufacturer and distributor websites, prioritizing factors like cost, availability, and multi-source support.

Tools:

– Seaker by Converge Lab is a free Beta application searches for electronic products using the specifications you input. It can also do part comparison and analysis.

– SnapEDA is a component search engine that provides symbols, footprints, & 3D models.

– Circuit Mind provides component search abilities, and can generate schematics around the selected component automatically.

6. Bill of Materials (BOM) Generation

AI can create consistent, formatted BOMs with multiple approved manufacturers and part numbers per line item, including cost data.

Tools:

– ChatGPT and similar AI platforms

7. Simulation and Modeling

When manufacturers don’t provide SPICE models, AI can generate them from datasheets or provided specifications—though engineers must verify accuracy.

8. Layout Assistance

Auto-routing has historically been limited in capability, but AI-assisted layout tools promise smarter placement and routing decisions.

Tools:

– Quilter is a layout tool that you supply constraints and a schematic and it generates the completed layout.

9. Fabrication and Assembly

AI can help source vendors based on schedule, cost, and manufacturing requirements, as well as perform automated DFM/DFA checks.

Tools:

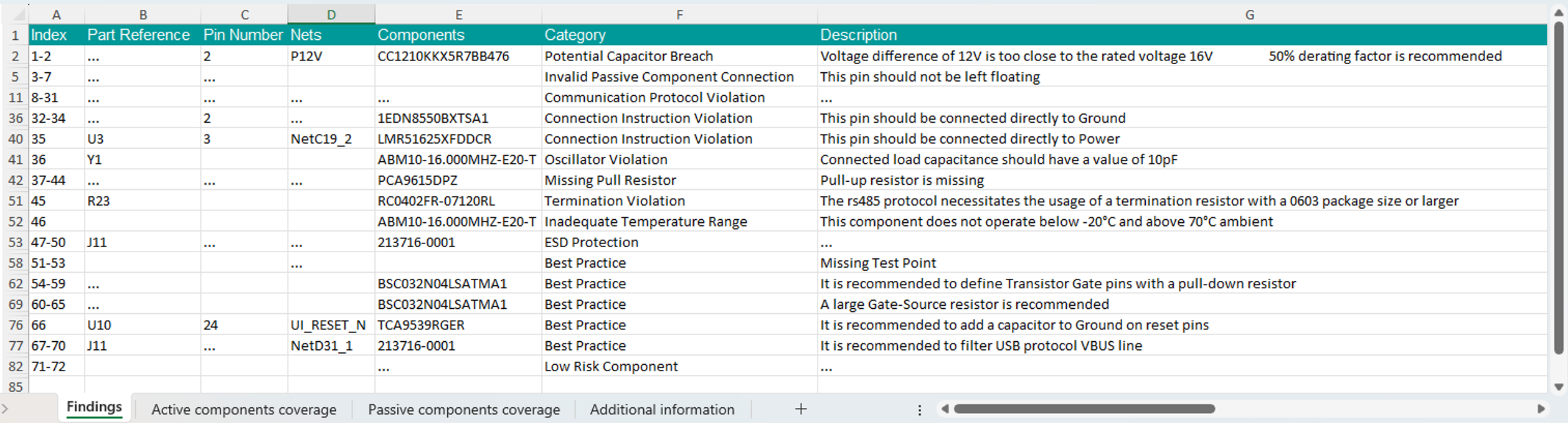

– CADY Solutions provides a spreadsheet listing issues like component rating and sizing issues, connection issues, and missing components too. It can even check interconnections between multiple boards.

Figure 1. CADY layout issue spreadsheet

– Converge Lab’s new tool takes a schematic and layout and generates a list of all issues. It uses AI to read datasheets to discover design issues that don’t match requirements in the specifications. With each issue, it will show the element in the datasheet that is not met. This keeps engineers from having to read entire datasheets, and letting the tool show issues that can be buried in fine print in a datasheet.

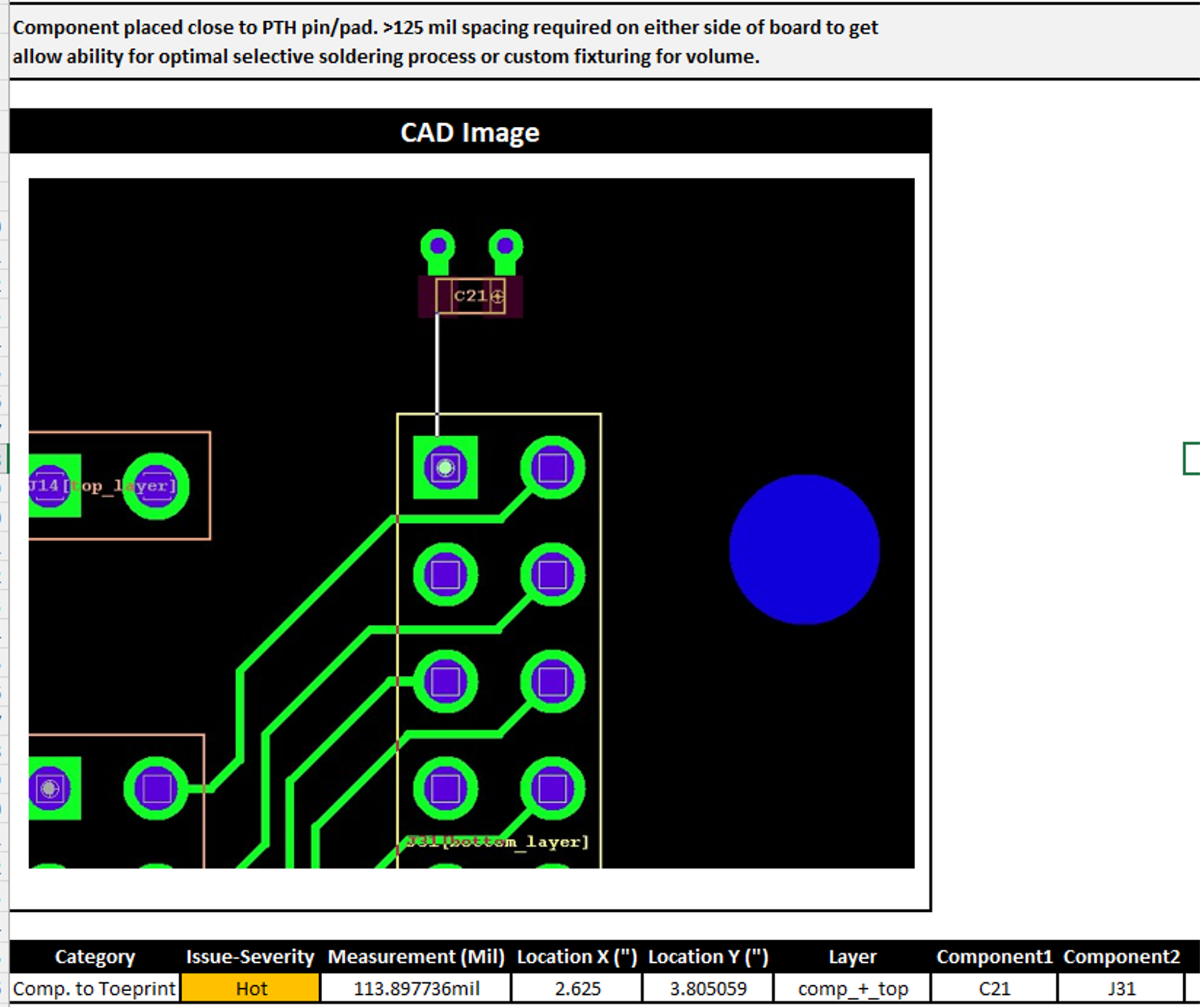

– WebDFM will provide descriptions and pictures of the issue it discovered facilitating your design updates.

Looking Ahead

This is only a small sample of AI’s potential in electrical engineering. While AI won’t replace engineers any time soon, it can significantly reduce the time spent on:

- Component searches

- Symbol creation

- Functional block drafting

- Schematic and layout checking

Future AI tools may:

- Suggest Integrated Circuits (ICs), generate functional schematic blocks, and place them in Computer Aided Design (CAD) tools

- Auto-complete partial schematics by adding missing discrete components and connections

Just as we moved away from drafting tables decades ago, we’re now moving toward minimizing manual digital drafting altogether.

Final Thoughts

I’m excited about AI’s potential to help us design reliable, cost-effective electronics faster. In spite of their widespread adoption in industry, AI tools are far from perfect. And, as previously stated, most of the tools listed cover lower-level tasks. It’s essential to recognize the limitations of the technology and when it should be more closely monitored or avoided altogether.

Here at Simplexity, we highly value responsible and careful use of AI tools to ensure safe design practices and ultimate design integrity. My passion lies in architecture and functional evaluation—tasks that require human insight. Human engineering and critical problem solving are still central to solid product engineering and design. However, for routine tasks like component selection, drafting, and documentation, I’m happy to let AI do a thorough first pass.

*Some of the tools listed are still in Beta as of this writing.