NEW PRODUCT INTRODUCTION (NPI) SERVICES OVERVIEW

In the following NPI Services Overview below, you can review a summary of the full menu of services we support as part of a New Product Introduction. Our NPI team can work with either your engineering team or ours and customize the service mix to fit your team and project needs.

How does our NPI team work with either your design engineering team or ours to help you bring your next innovation to market?

NPI incorporates planning, engineering collaboration, verification and manufacturing readiness into a coordinated new product development plan.

SIMPLEXITY’S NPI TEAM PROVIDES SUPPORT IN FOUR MAIN SERVICE AREAS:

- Planning and Project Management

- Concurrent Engineering Collaboration with design engineering teams

- Product Verification

- Manufacturing Readiness including Contract Manufacturing and Tooling vendor selection, onboarding, and monitoring.

PROJECT MANAGEMENT

New Product Introduction includes considerable moving parts and processes. Our efficient planning tools and dedicated project managers keep everything on track. Estimated costs, schedules, interdependencies, milestones, and supply chain strategies are clearly defined and documented along the way.

NPI Project Management Services include:

- Product Build Planning

- Manufacturing Schedule Management

- Resource Management

- Vendor Management

- Cost Management

- Supply Chain Strategy

CONCURRENT ENGINEERING

Simplexity’s NPI team is integrated with the design engineering team to ensure NPI is a seamless extension of the product development process.

Together, we establish that critical performance metrics are met and monitored. We also ensure that Design for Manufacturing, Assembly and Serviceability requirements are met. Root Cause Analysis and defect resolution is built into the design verification process before transfer to manufacturing.

Concurrent Engineering Services include:

- CPM Development

- DfX Processes

- Design Transfer

- RCA / Defect Resolution

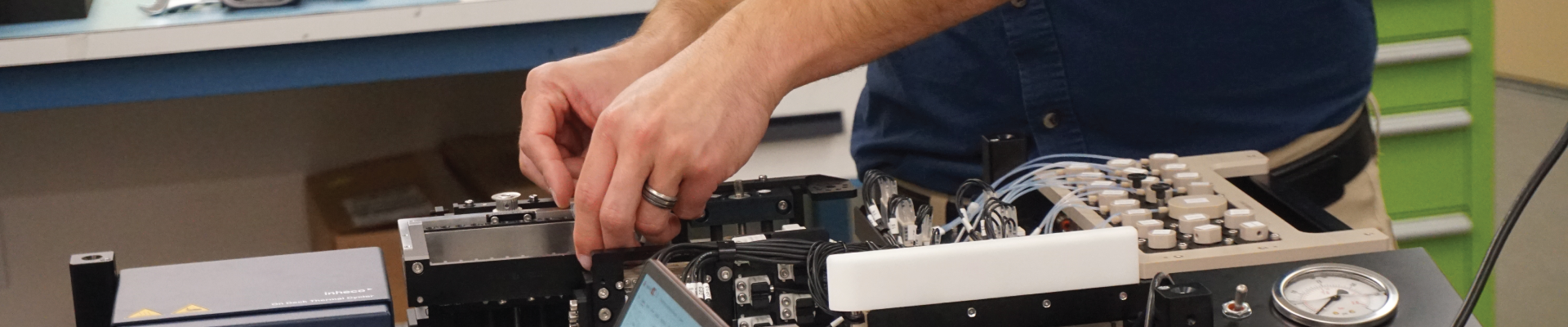

PRODUCT VERIFICATION

Our team conducts iterative pre-production builds and thorough engineering characterization testing to ensure design integrity. Reliability Testing ensures product flaws are identified and Regulatory Testing provides verification that any needed certifications or safety requirements have been met.

Product Verification Services include:

- ECT Builds & Test

- PP Builds & Test

- Reliability Testing

- Regulatory Testing

MANUFACTURING READINESS

Selecting and onboarding the right tooling and contract manufacturers is critical and our team helps clients ensure manufacturing partners are optimized to fit project needs. Within our robust Quality Management System, we verify design quality metrics are met and processes suggested by manufacturing partners are well vetted and validated. We offer onsite build supervision until the product is well established.

Manufacturing Readiness Services include:

- Tooling Vendor Selection

- CM Selection & Onboarding

- Quality Metrics Verification

- Process Validation

- Onsite Build & Test Supervision

Contact Simplexity to discuss how our New Product Introduction (NPI) team can help you get your next innovation to market.