CASE STUDY: CUSTOM SYRINGE AND AIR DISPLACEMENT PUMP

![]()

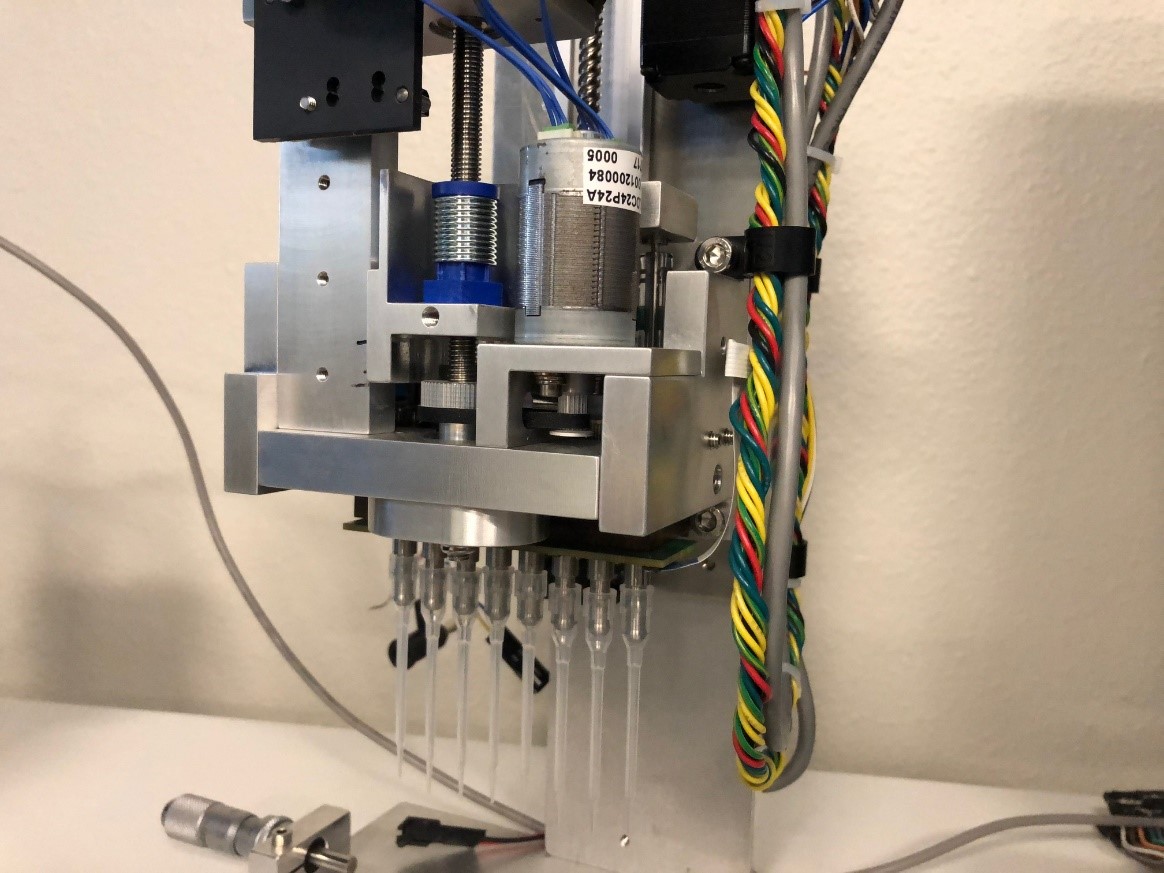

THE PRODUCT

- Pump for automated liquid handling application

OUR ROLE WITH THE CUSTOM SYRINGE AND AIR DISPLACEMENT PUMP

- Lab prototype development of compact and low-cost metering pumps

- Custom Brushless and brush DC servo motor drives

- Custom encoder solution

- Final production units to be die-cast aluminum and injection molded plastic parts

The pump is an essential element of an automated liquid handling robot, and Simplexity has developed custom syringe and air displacement pumps in which the engineering cost was more than offset by the resulting savings and miniaturization. Simplexity-designed custom pumps typically cost about 1/8th as much as a generic pump. Additionally, Simplexity can add special functionality either not found in generic liquid handling robots or that would otherwise be excessively expensive.

A Fortune 50 Life Science company approached Simplexity with the need to develop a syringe pump-driven, 8-up liquid handler to displace fluids on standard well plates. Unlike other solutions that use stepper motors, the Simplexity design used a closed-loop servo drive system. The client needed both liquid level and bubble detection. As part of the sensor packaging development, we accomplished liquid level detection using a capacitive sensor and bubble detection through a pressure sensor.