CASE STUDY: BULLSEYE CUSTOM GOLF BENDER

Designing for unprecedented speed and precision.

THE CHALLENGE

To the serious golfer, the knowledge that each club in their bag is set up to perform optimally just for them inspires confidence and improves their game. In the past, TaylorMade adidas Golf (TMaG) company would have their operators place a user’s club into a clamp, and then manually bend the club to the desired custom angle. This was both physically challenging for the operators and accuracy was based on a visual scale, subject to human judgement. TMaG chose Simplexity to develop an automated tool for bending custom angles into golf clubs, as requested by each user. The tool needed to exert a large load to bend the club, be accurate, be repeatable, and perform the operation faster than an human operator could it alone.

THE SOLUTION

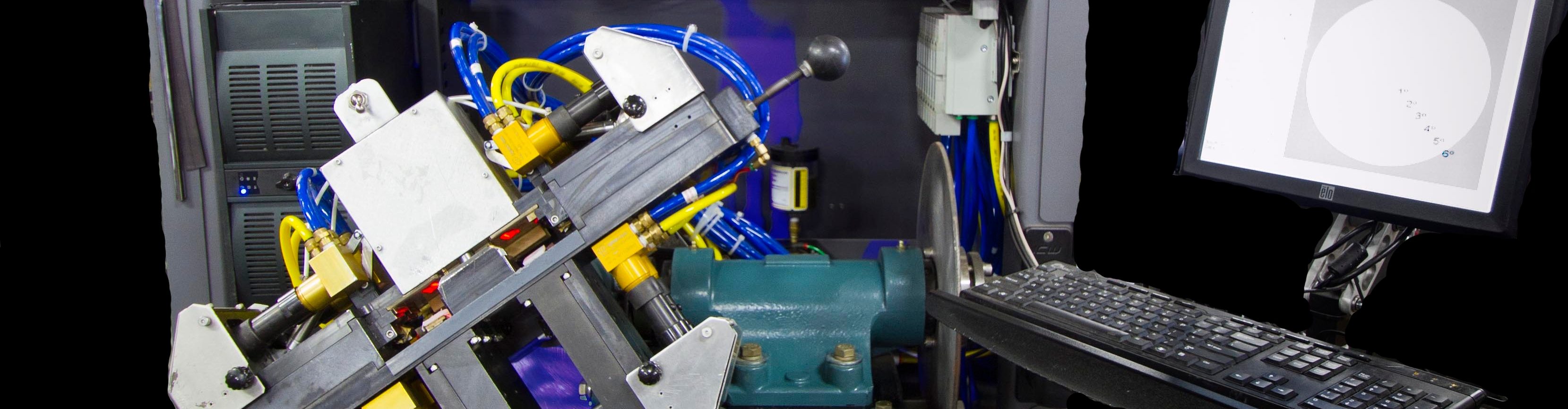

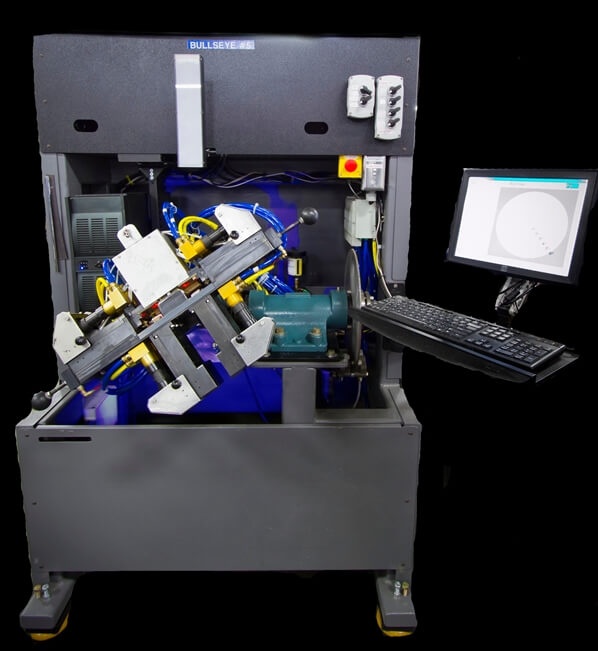

Simplexity built a unique manufacturing tool that brings custom precision to the manufacturing floor that adjusts the loft and lie angles of golf clubs with unprecedented speed and precision.

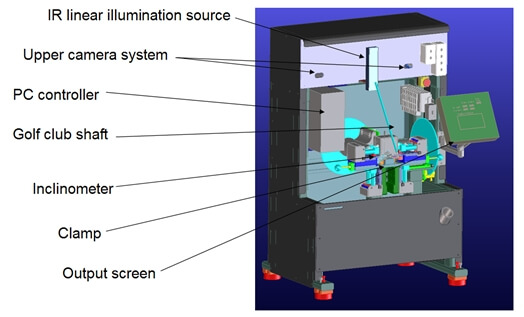

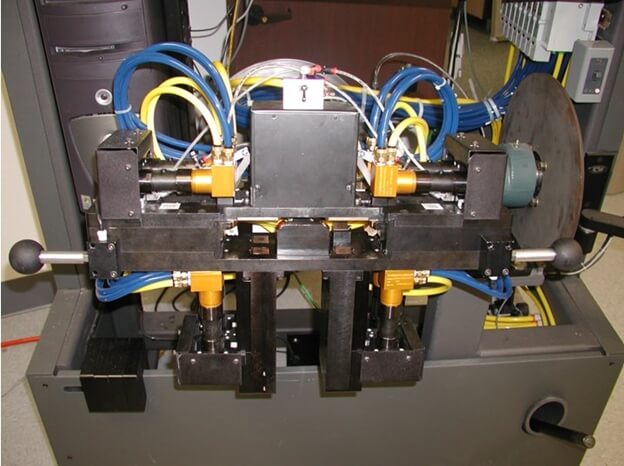

Bullseye is the world's first optically-based 6-DOF instrument capable of both measuring loft and lie angles to ultra-high precision, and enabling the operator to adjust those angles with state-of-the-art accuracy. The upper camera system measures the angle of the golf club shaft in space, while the inertial inclinometer measures the orientation of the club face with respect to gravity. At the same time, a third camera in the clamp reports the angle of the lie lines inscribed on the face of the club.

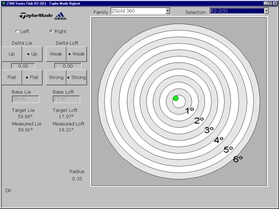

Together these variables are used to calculate loft and lie angles, and the deviation of those angles is graphically displayed in real time on the output monitor. The highly intuitive GUI enables even untrained operators to quickly and accurately adjust club angles to meet the specification.

HARDWARE

- Upper camera system: measures the angle of the golf club shaft in space.

- Lower camera system: measures the inscribed lie lines on the face of the club.

- Highly intuitive GUI: enables even untrained operators to quickly and accurately adjust club angles into spec – in real time – performing the actual bend.

- Inertial inclinometer: measures the orientation of the club face with respect to gravity.

- Third camera in the clamp: reports the angle of the lie lines inscribed on the face of the club.

OPERATION

- Operator loads club into bender.

- The hardware calculates the loft and lie angles of the club.

- Operator inputs new required loft and lie values into GUI.

- Machine bends club to required values and graphically displays them in real time on the output monitor.

IN ACTION

RESULTS

This unique piece of industrial production equipment showcases Simplexity’s ability to integrate mechanical, electrical, and optical components with intelligent software design. Built and assembled in-house, it stands 80” tall and occupies a modest 44” x 32” footprint. Bullseye units have been working in a factory setting for more than a decade delivering reliable and profitable performance for this sporting goods manufacturer.

OPERATION

- Operator loads club into bender.

- The hardware calculates the loft and lie angles of the club.

- Operator inputs new required loft and lie values into GUI.

- Machine bends club to required values and graphically displays them in real time on the output monitor.