At Simplexity, part of our work is designing embedded motion systems. As embedded motion engineers, we have to know how the smart electronics get placed within the physical structure (“embedded”) and how each component moves relative to each other (“motion”). In this three-part series, I delve into how we describe and model the latter term, motion, which we often take for granted as being quite simple.

In the last post of the series, I provide some final considerations for analyzing 3D motion. When we model motion to help solve engineering problems, we must be careful to use the most appropriate model. Sometimes the simple, back-of-the-envelope equations will be sufficient, but other scenarios might require tools beyond what can be found in classic online and textbook sources.

Modeling complex motion phenomena

When we model complicated 3D motion phenomena, it’s key to distinguish between scalar and vector quantities. Remember, a vector has both a magnitude and direction (e.g., 25 mph in the northeast direction), while a scalar is something that just has a magnitude (25 mph). When we bring into our model velocities, accelerations, linear and angular momentum, forces, torques, and so forth, we should first think of them as vector quantities. For instance, when we talk about torque, it’s useful to specify both its direction (e.g., about the positive z-axis), as well as its magnitude (5 N-m).

The benefit of using a more complex model is that you can precisely define all the quantities related to angles (the orientation, angular velocity, angular acceleration, angular momentum, moments, and products of inertia) for any motion system made up of rigid bodies. Beware that the equations can get gnarly. For complex systems it can be beneficial to use software programs like MATLAB, Working Model, or MotionGenesis.

Note that if I were following the 3D model methodology in my gear example, then I would explicitly treat the velocity and angular velocity as vector quantities. But again, the motion in the gear example fits my criteria for simplifying down to 2D kinematic equations. If my system has a more complex motion, then I must treat the kinematic and dynamic quantities as vectors. This is the crucial first step to appropriately analyze any motion system.

The intermediate axis theorem

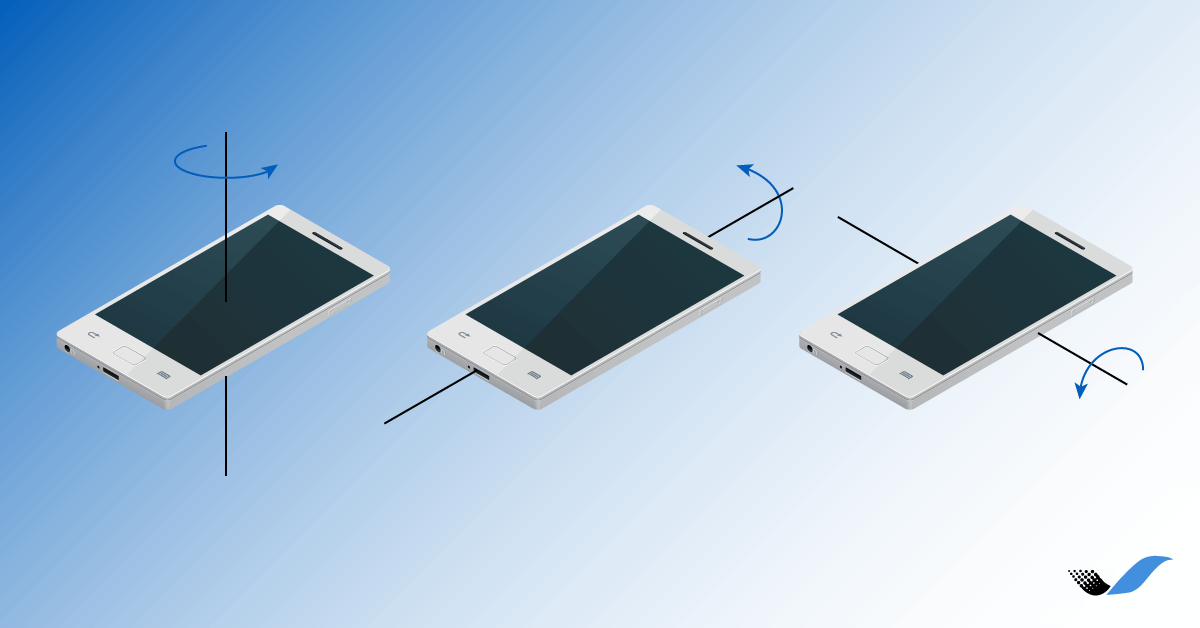

I’ll end with a fun application called the intermediate axis theorem. The theorem says that if you try spinning an object on its intermediate axis, the imperfections in how you spin it will cause the motion to be unstable. This is the same principle that explains why it’s difficult for planes to get out of flat spin. It also explains that if you toss and spin your cellphone independently around each axis, the motion will be stable for two of the axes but unstable for the intermediate axis. (Be careful, but give this a shot: toss and spin your phone about each of its three axes, and you’ll notice that one of the axes has a very unstable spin. That axis is the phone’s intermediate axis.) I have a very poor intuition for why this happens, but I don’t necessarily need intuition to explain why it happens: with using the more complex, vector-based 3D framework model we can actually model and simulate the behavior mathematically.

Precisely modeling the motion of a system can be a tricky thing, but by constructing a robust model we can more quickly respond to broader concerns. If we desire to make a stable motion system that is functionally robust, smooth, and elegant, then we have to decide which model is more appropriate. As engineers, it’s critical for us to realize the limitations of the commonplace 2D equations, and that there are other appropriate tools to solve 3D motion systems.

For more resources and support for topics related to 3D motion analysis, follow Simplexity’s product development blog.